White papers

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

A.G. Stacker, a manufacturer of advanced stackers, partners with Ewon to offer innovative remote connectivity solutions, improving customer support and reducing travel costs while enhancing machine performance.

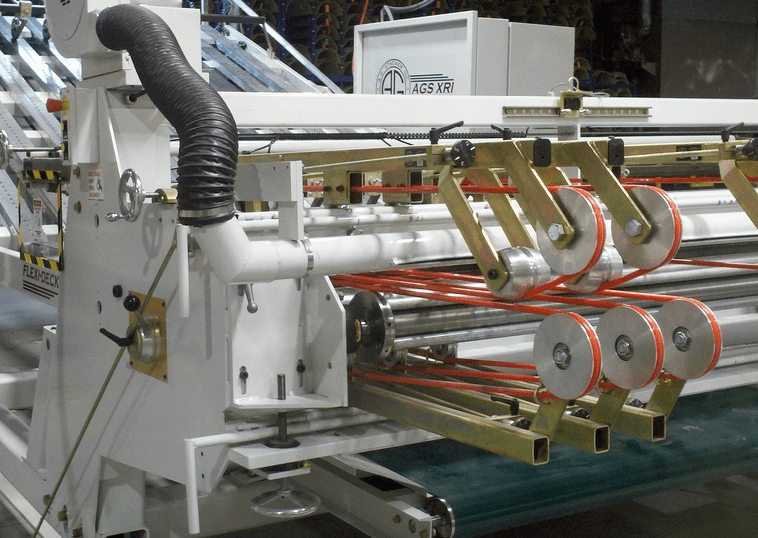

A.G. Stacker is a manufacturer of state-of-the art Stackers and ancillary equipment. When company owners Clarence and Helen Allen launched the company in 1996, they had a goal to provide innovative equipment with better customer support than anyone in the industry. Today, keeping innovation and customer service in mind, A.G. Stacker made the decision to work with Ewon to develop the next generation of customer interaction.

A.G. Stacker’s machines have been adopted by customers around the globe. Each of these machines employs a sophisticated automation system including drives, programmable controls and other state-of the art devices. Every machine goes through a rigorous test process prior to leaving A.G. Stacker’s Virginia-based facility. While A.G. Stacker has a highly trained team of engineers, technicians and trainers to assist customers in maximizing machine value, customer conditions sometimes warrant fine-tuning and system modifications in the field.

Automation equipment on live machines sometimes requires someone to travel out to the customer to make even small changes. With the cost of last minute flights skyrocketing, A.G. Stacker sought a new and innovative way to address the problem. This is where Ewon was called into the situation.

At the heart of the matter, time spent traveling can be better used by our people and downtime at our customers is very expensive.

Kennedy Larramore, Electrical/IT, A.G. Stacker

Taking a unique approach to the challenges of remote connectivity, Ewon has developed a set of products that provide a fast and easy approach to remote connectivity all the while addressing users concerns about network safety and security.

To understand A.G. Stacker’s approach we spoke to Kennedy Larramore who serves as an Electrical/IT Tech. “Even though we have three techs assigned to assisting our customers, ‘road techs’ are costly for both our customers and A.G. Stacker. At the heart of the matter, time spent traveling can be better used by our people and downtime at our customers is very expensive. Further, we often encounter issues where the customer has a difficult time describing the exact nature of the problem,” reports Larramore.

Kennedy went on to say, “We started out providing the Ewon devices as an option on our machines. But after witnessing the power of Ewon’s free Talk2m software and the devices in the field, we have made Ewon a part of every machine we build.” As we continued our conversation, Mr. Larramore added, “We are currently working to retrofit our existing machines already running in the field to Ewon connectivity.”

Progressive companies like A.G. Stacker continue to match innovative technologies with customer needs to create world-class customer service.

When asked to elaborate on why A.G. Stacker prefers the Ewon over other connection methods, we heard the following: “Using Ewon is unimaginably easier than traditional approaches to accessing via the customer’s network. Working with the customer’s IT department typically involves many discussions and continuing issues as their firewall goes through normal modifications to ward off new threats.” Ewon addresses those issues and more.

Aside from the innovative customer service to which A.G. Stacker is committed, there is a tangible payback. Kennedy related a story of the Ewon devices in action: “Recently we had a customer who experienced a major electrical disturbance generated by a lightning strike. We feared parts of the program resident in the machine’s Human Machine Interface System (HMI) were compromised. Using remote connectivity afforded by the Ewon system, we were able to quickly get the customer up and running without a visit to their facility, which would have been required in the past. Furthermore, we feel strongly the system saves us at least one trip per month. And, that is a huge difference.”

But A.G. Stacker does not “just” use Ewon for remote access. They have added a camera system to their machines which allows A.G. Stacker’s expert team to watch the machine in action. They are often able to identify root causes of issues which are not immediately apparent to the customer.

Installing and enabling the Ewon is easy. “Once set up, logging into a remote machine can be accomplished by pushing a single button. The initial set up takes around 10 minutes”.

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Our products solve everyday industrial communication problems. Discover how our customers have improved their business with HMS case studies.

HMS communication solutions help thousands of companies solve specific communication problems in many different industries and applications.