Over time, different protocols have gained popularity in different regions and industries. For example, PROFINET is common in Europe, EtherNet/IP holds significant market share in North America, and EtherCAT and CC-Link are popular in Asia, particularly in Japan. To ensure your device's success in a global market, it must be able to connect to multiple industrial protocols.

Every year, HMS Networks conducts a comprehensive analysis of the industrial network market, aiming to estimate the distribution of new connected nodes by type and protocol within factory automation.

However, supporting multiple protocols requires a deep understanding of both hardware and software architectures. These are inherently complex and diverse for each protocol, although they seem common at first sight.

The Anybus CompactCom addresses these challenges by providing a comprehensive communication solution. Unlike most alternatives, it integrates both hardware and software into a single module.

1. Complete communication module: The Anybus CompactCom supports all major industrial and cloud protocols. With just a single development cycle you can easily connect your products to all your chosen protocols.

2. Lifecycle maintenance: HMS maintains both hardware and software throughout the product's lifecycle, including regular updates to network specifications.

3. Available in three form factors:

4. Pre-certified for easy integration: Simplifying the transition to full certification and ensuring compliance with industry standards.

5. Flexible hardware interface: Supports parallel, SPI, and serial communications, offering versatile integration with different host microcontrollers.

6. Powerful software interface: A free of charge and OS independent, C language driver that can be compiled with your application software.

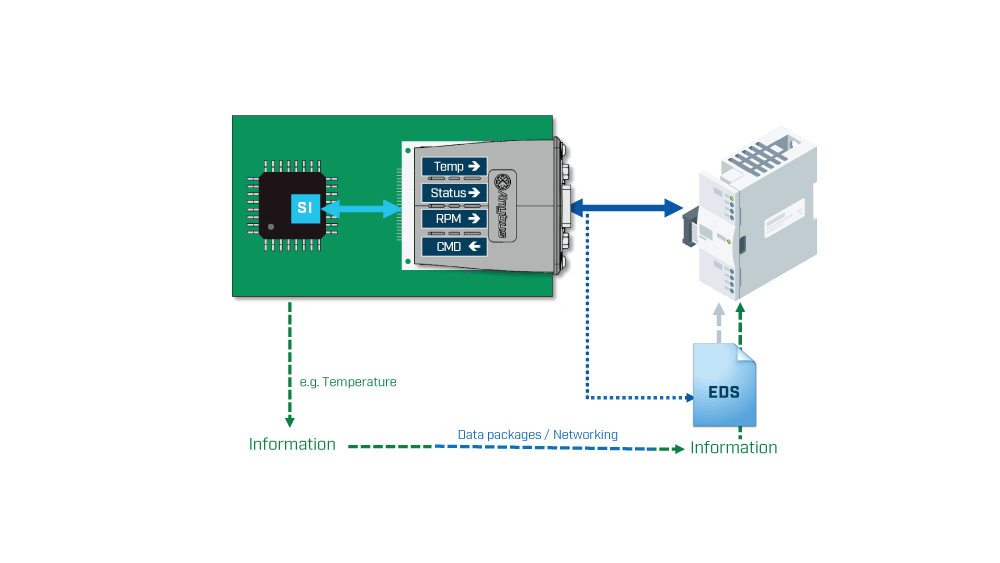

The Anybus CompactCom design principle is the key to understanding its design advantage. The Anybus CompactCom operates in automation devices as a communication node unit, connecting the host device to a PLC controller and exchanging process variables and information. This architecture is significant because it decouples the specifics of protocol management from the core application logic, ensuring seamless integration across different protocols.

Figure 1 The Anybus CompactCom connects the Host and the Master.

For manufacturers of automation devices, this setup simplifies the communication between their microcontroller applications and the controlling devices, allowing developers to focus on their application rather than the intricacies of each communication protocol.

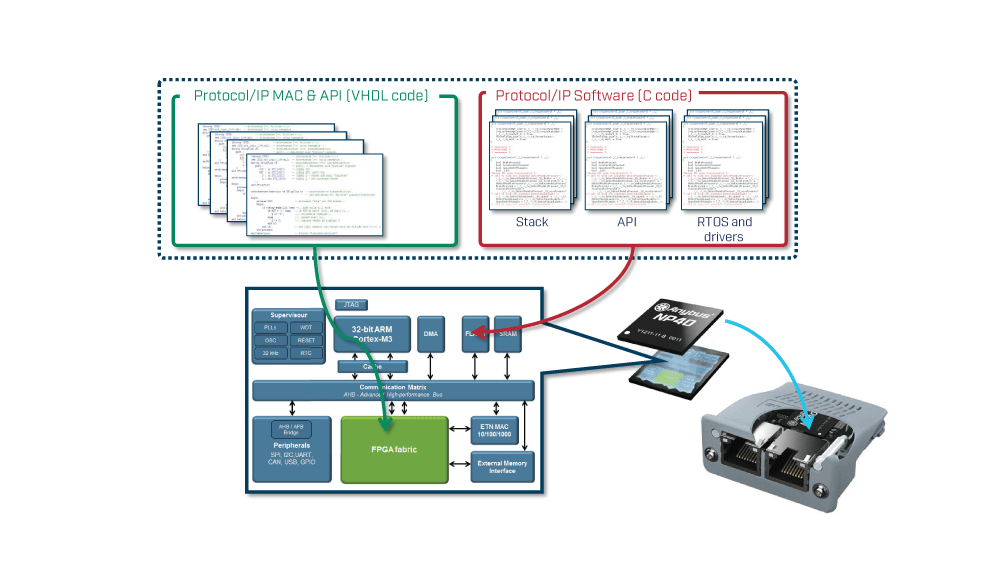

At the heart of the Anybus CompactCom is the NP40, a custom-designed chip combining programmable hardware and software.

- Microcontroller and FPGA: The FPGA handles protocol-specific logic (e.g., real-time switches for PROFINET or standard EtherCAT interfaces), while the microcontroller runs a real-time operating system to manage protocol stacks.

- Standard API: The supplied API provides a consistent software interface between the NP40 and your host microcontroller, ensuring seamless software interfacing despite internal protocol differences.

Figure 2 The Anybus CompactCom provides programmable hardware and software.

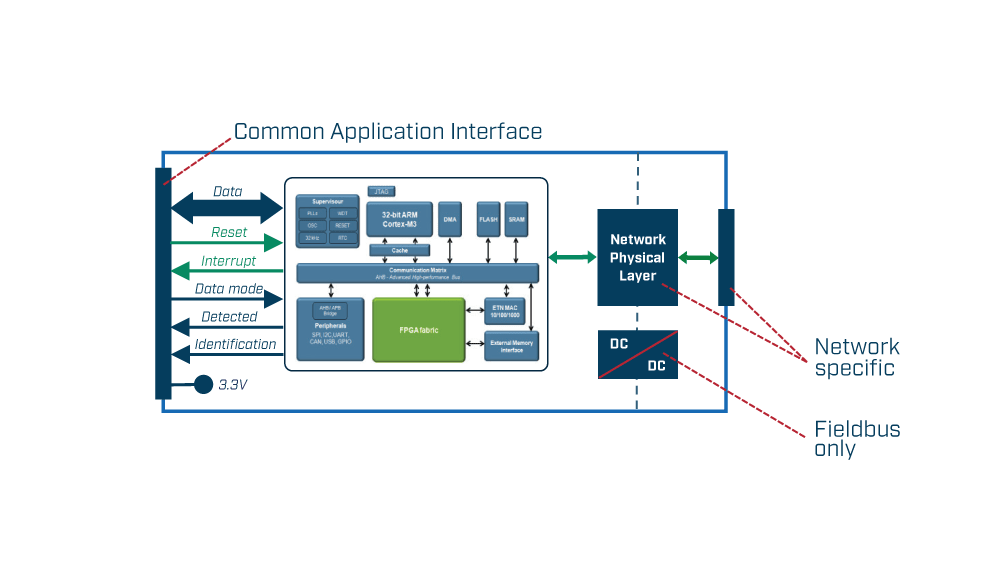

The Anybus CompactCom provides hardware and application interfacing options which can be tailored to meet your needs. Key components and considerations:

1. Data modes:

- Parallel: Uses 8 or 16 bits in parallel for high-speed data exchange.

- SPI (Serial Peripheral Interface): A fast data exchange up to 20 MHz, simplifying complex designs.

- Serial: Slower data-rate, supported for legacy systems.

2. Flow control and reset:

- Reset line: Connects to an output port of the microcontroller, allowing the NP40 to be reset from software.

- Interrupt line: Switch program flow for specific events.

3. Hardware detection and identification:

- Application can test whether an Anybus CompactCom module is mounted, and which model it is, directing the startup procedure.

4. Power supply:

- Requires a 3.3V power supply to operate.

Figure 3 The Anybus CompactCom’s hardware and application interfacing.

Figure 3 The Anybus CompactCom’s hardware and application interfacing.

The API of the Anybus CompactCom is driven by the software interface and provides several options which can be tailored to meet your needs. Key components and considerations:

- Variable management:

- Application Data Instances (ADIs): Define network variables (ADIs) in your software, specifying names, data types, element counts, and value ranges. Uses pointers for seamless data management between the Anybus CompactCom and your application. Can be statically or dynamically implemented.

- Acyclic and real-time data handling: Manage acyclic requests (non-time-critical) and real-time data exchange efficiently through the provided software layers.

- Network Administration:

- Network objects: Set up network-specific administration tasks, such as vendor IDs, to ensure smooth operation across different protocols.

- Function Calls:

- Keep alive and interrupt; Basic calls to facilitate interface software operation.

- Additional functionalities:

- Ethernet goodies: Calls and objects to manage the webserver, email sending, FTP exchange, JSON, and many more.

HMS also provides the Anybus CompactCom IIoT Secure, a variant which offers secure communication with IIoT applications using the OPC UA or MQTT data exchange methods. To ensure communication is secure, the Anybus CompactCom IIoT Secure includes the following:

1. Certificate management: Ensures that all communications are authenticated and secure.

2. Encryption: Protects data during transmission to prevent unauthorized access.

3. Secure device: Guarantees that the device itself is protected against tampering and cyber threats.

4. Secure boot: Ensures that the device only runs authentic software, protecting against malicious code.

When integrating the software, you can specify which variables need to be exchanged with the local controller and which ones will be sent to the digital applications. Once configured, the Anybus CompactCom will ensure seamless and secure data exchange.

The Anybus CompactCom stands out as a comprehensive solution for embedded industrial communication, offering unparalleled flexibility and ease of integration. By combining robust hardware with sophisticated software support, it eliminates the complexities and hidden costs associated with multi-protocol development, making it the ideal choice for manufacturers aiming to stay competitive in a global market.

For more information on the Anybus CompactCom, see our solution page: