In water management, ensuring efficient and uninterrupted operations is crucial. Industrial networks serve as the foundation of operations, making their diagnostics vital for maintaining a continuous supply of water. This article explores the advantages of adopting a proactive maintenance approach for industrial networks within the Water and Wastewater industry.

Thirty years ago, systems and machines operated independently, without the benefit of industrial networks. While those systems were innovative for their time, a comparison with today's technology highlights the remarkable advancements we've achieved in speed, production volumes, and efficiency. However, with these improvements have come an increase in complexities and the time required to resolve them. In the past, production line issues were straightforward to address; Today, the very machines that have elevated our capabilities demand more attention, and diagnosing problems is far more challenging.

A robust network infrastructure serves as the backbone of any water management system. Without it, the smooth operation of pumps, valves, sensors, and control units would be jeopardized. For water infrastructure managers, ensuring network reliability is not merely a priority—it's a necessity for operational success.

Reliable network infrastructure enables real-time data exchange among the various components of the water system. This connectivity is crucial for making timely and accurate decisions regarding water distribution, treatment, and quality control. In an era of digital transformation, where data-driven insights are essential, a sturdy network foundation is critical for effective water management.

Industrial networks undergo various changes over time that can challenge their efficient operation. Key factors include:

1. Aging Infrastructure: Many water systems depend on legacy systems and often implement regular updates involving new components, communication devices, and additional layers. This complexity can lead to network issues that necessitate specialized knowledge and skills for effective troubleshooting.

2. Network Congestion: As networks incorporate more devices and sensors, congestion can become a significant problem. This congestion may result in delays in data transmission, ultimately causing inaccurate insights and poor decision-making.

3. Environmental Conditions: Various environmental factors can threaten network stability. Issues like moisture, temperature fluctuations, and electromagnetic interference can degrade performance. Implementing protective measures and using diagnostic tools to detect environmental impacts can help mitigate these risks.

4. Cybersecurity Threats: As water systems become increasingly digitized and ethernet-based networks expand, the connectivity between networks and facilities is also on the rise, resulting in greater exposure to cyber threats. Implementing thorough diagnostic strategies is essential for identifying vulnerabilities and fortifying the network against potential breaches.

5. Employee shortage: The water industry faces a critical shortage of skilled employees, impacting maintenance and operational efficiency across industrial networks. This shortage is worsened by regional disparities, technology adoption, and ongoing workforce trends, creating challenges in service quality and system reliability. Using remote access technologies can help alleviate workforce shortages by enabling technical experts to diagnose and address issues without needing to be on-site. This approach improves efficiency, ensures quicker responses to operational disruptions, and reduces both costs and CO2 emissions.

Addressing these challenges is vital for ensuring the reliability and efficiency of industrial networks.

The key to effective network maintenance lies in shifting from a traditional reactive approach to a proactive one, which offers several significant benefits:

a) Enhanced Operational Efficiency: Proactive maintenance guarantees that all network components operate at their best, minimizing the risk of unexpected failures. This results in smoother operations and more efficient water processing and distribution.

b) Reduced Downtime: By conducting regular inspections and maintenance, potential issues can be identified and addressed before they escalate into major disruptions. This proactive stance significantly decreases downtime, ensuring a consistent and reliable water supply.

c) Cost Savings: Implementing proactive maintenance can avoid costly emergency repairs and extend the lifespan of equipment. By tackling minor issues early on, you can prevent them from evolving into major problems that necessitate expensive fixes or replacements.

d) Improved Compliance and Safety: Regular maintenance ensures that all systems adhere to regulatory standards and operate safely. This is particularly vital in the water industry, where compliance with health and safety regulations is essential for protecting public health and avoiding legal repercussions.

Let's examine an example of both strategies.

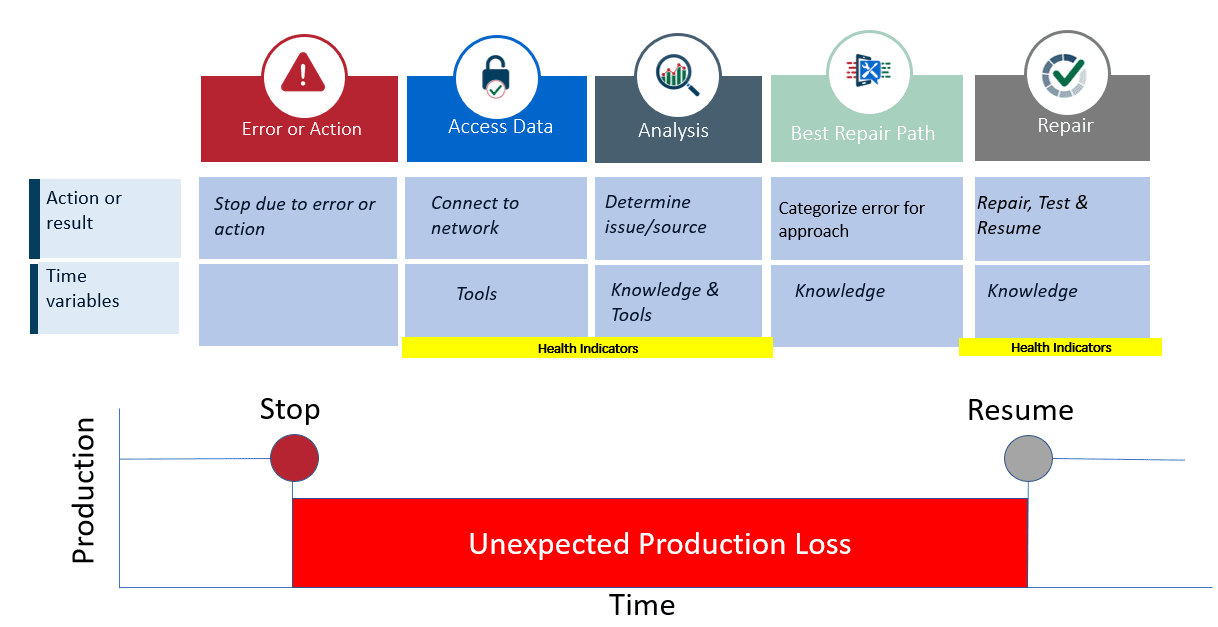

As illustrated in Figure 1 below, production is halted from the moment an error occurs until the final test during the repair stage, ensuring that the issue has been resolved.

Fig.1 Reactive Troubleshooting Process

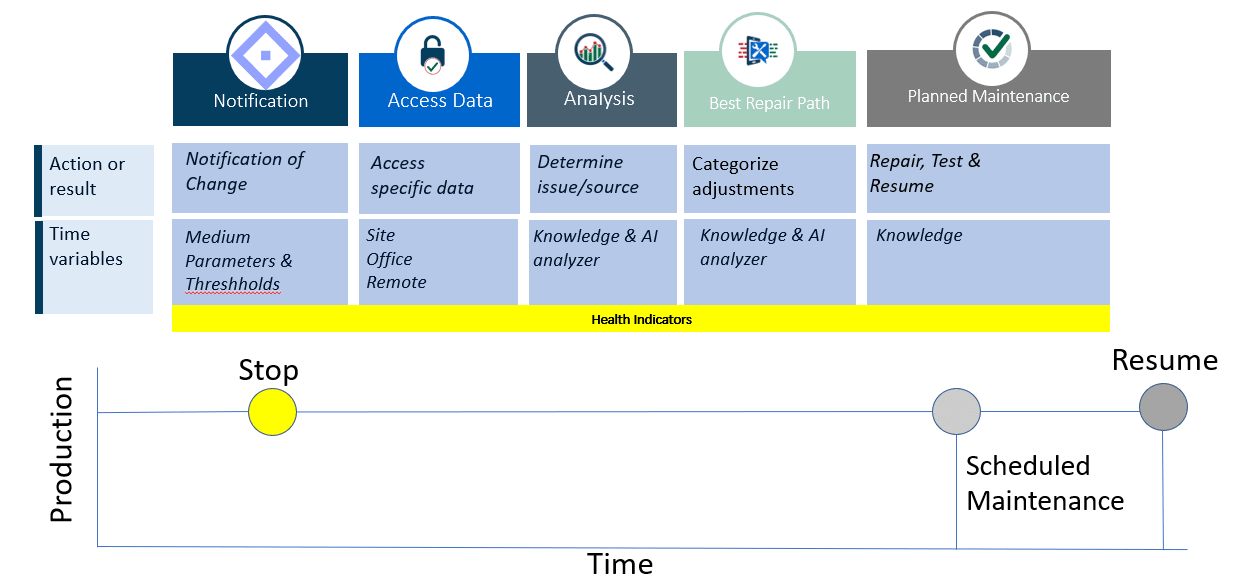

In Fig. 2, the initial step involves a notification rather than an immediate error. This approach ensures that production continues uninterrupted, with repairs scheduled for the next planned maintenance session.

Fig.2 Proactive Troubleshooting Process

The realm of industrial network diagnostics is rich with innovative tools and technologies designed to optimize network performance in Water OT applications. These tools offer varying degrees of analysis and monitoring capabilities, catering to the diverse needs of water infrastructure managers and OT engineers.

ProfiTrace is a tool particularly for those managing PROFIBUS networks. It provides detailed insights into network health, enabling users to quickly pinpoint and rectify issues. Its user-friendly interface and real-time data analysis make it an essential asset for maintaining network stability.

ComBricks, another powerful tool, extends the capabilities of network diagnostics by offering continuous monitoring. Its modular design allows for flexible implementation across different sections of the network, ensuring comprehensive oversight and timely issue resolution.

Atlas2, which delivers unmatched insight into industrial network health and topology, monitoring PROFINET and other ethernet based industrial networks, and enabling intelligent predictions to prevent issues and empower proactive solutions over reactive responses.

Implementing effective network diagnostics requires a strategic approach that includes careful planning, execution, and a commitment to continuous improvement. By following best practices, organizations can optimize their network performance and minimize the risk of unexpected downtime.

Regular Maintenance and Updates: Routine inspection and updates of network components are essential to reduce the likelihood of malfunctions. This process involves replacing outdated hardware, updating software, and conducting periodic performance assessments.

Integration of Monitoring Tools: Equipping networks with diagnostic tools such as Atlas2, ProfiTrace, and ComBricks provides organizations with real-time visibility into their network health. This proactive monitoring facilitates early detection of anomalies, allowing for prompt corrective action.

Training and Education: Maximizing the effectiveness of network diagnostics relies heavily on training and education. By empowering staff with the knowledge to utilize diagnostic tools effectively, organizations enhance their ability to maintain network integrity. Regular training sessions and workshops ensure that teams stay informed about the latest advancements in network diagnostics.

Real-world examples offer compelling evidence of the impact of network diagnostics in Water OT applications. The case of the Rijnland District Water Control Board serves as a testament to the effectiveness of diagnostic tools in ensuring network stability and operational efficiency.

Faced with recurrent malfunctions in their PROFIBUS network, Rijnland turned to Anybus Diagnostics for a solution. By employing the ProfiTrace tool, they were able to swiftly identify and rectify the issues, restoring network functionality. To safeguard against future disruptions, they implemented ComBricks modules for continuous monitoring.

The results were impressive. Rijnland witnessed a significant reduction in unplanned downtimes, ultimately enhancing water quality across their 1,100-square-kilometer jurisdiction. This case underscores the value of adopting robust diagnostics to mitigate network challenges and optimize performance.