HMS communication solutions allow you to:

- Connect machines to any network

- Ensure uptime with network diagnostics

- Trace and digitize food production

- Do remote maintenance

- Optimize energy use

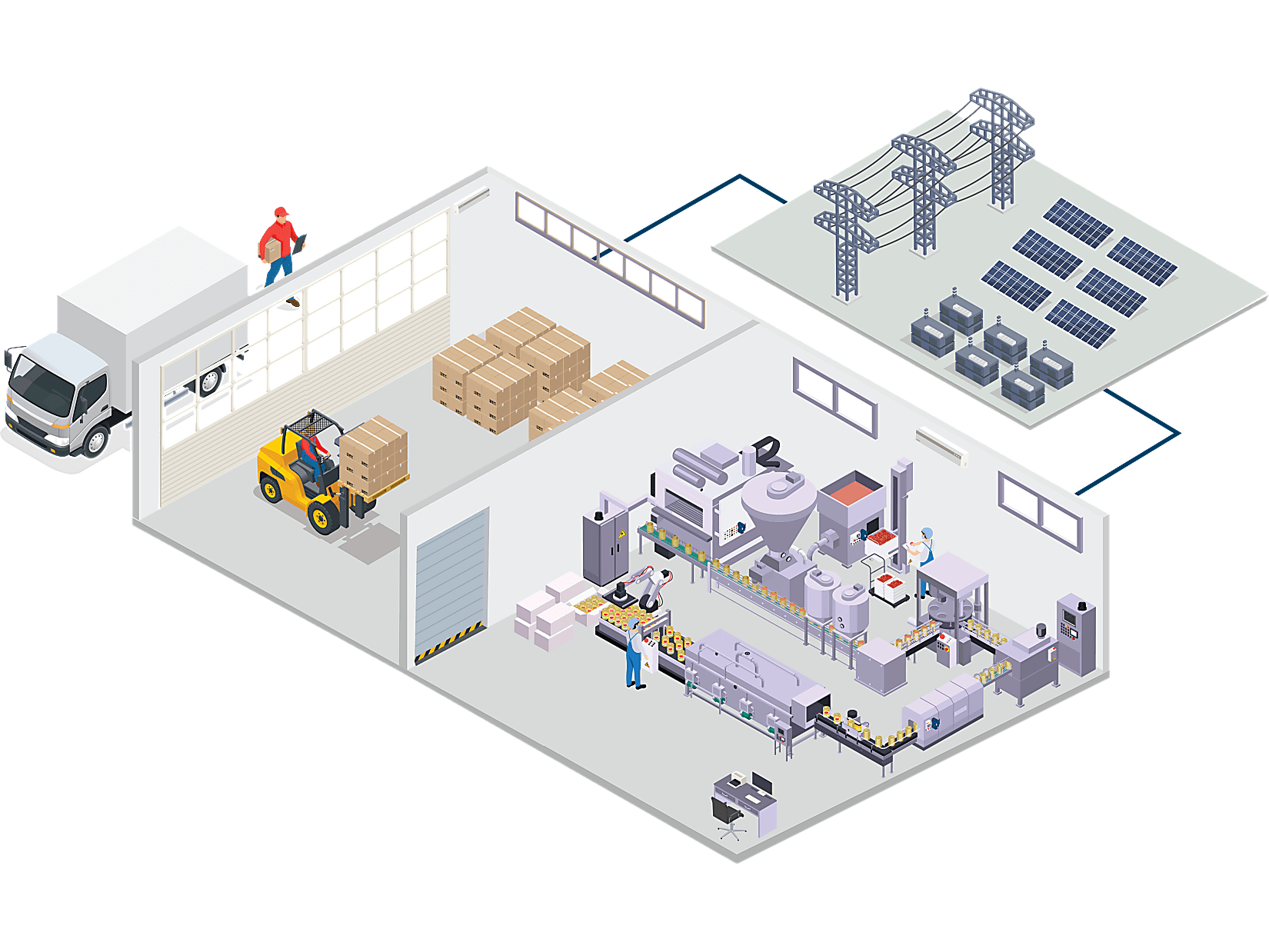

A food processing plant contains many different machines and systems. HMS solutions enable them to communicate in an efficient, secure and sustainable way. Industrial networking, remote access, machine data visualization, connecting to safety networks and much more.

Food processing lines are usually made of a unique combination of machines for dosing, mixing, kneading, heating etc. The machines come from many manufacturers using different communication technologies.

Anybus solutions from HMS Networks enable food and beverage machines to communicate on any industrial network.

Food production traceability requires a controlled process with constant access to machine data. For example, a fast reaction when the temperature of a cooling chamber is getting out of range is critical to reduce waste.

Ewon remote solutions from HMS help you gather data from your machines, even legacy ones, and visualize this data on screen. You get access to all information about your machine and get notified of specific events via email or text messages.

OPC UA or cloud connectivity allows you to centralize data to optimize production quality and efficiency — any data, any time, anywhere.

Minimize your energy bill and meet the increasing demands for sustainability and energy optimization. Heating and cooling equipment are big energy consumers but so is other building equipment.

HMS communication solutions help you to network and collect energy information from any machine or device, to create energy consumption reports and define your optimization potential and strategies.

See how Lagafors in Sweden can remotely access their cleaning systems for food processing.

Machines for packaging, bottling etc. are getting faster, more flexible and more complex. Quick reaction time and highly skilled maintenance staff is needed to troubleshoot them.

HMS simplifies the service procedure for production machinery with easy and secure 24/7 remote access for machines.

Thierry Bieber, Industry Manager at HMS Networks discusses current trends and technologies in food and beverage processing.

Different networks and protocols are used in different parts of the world. But according to our study of the factory automation market, EtherNet/IP and Profinet are the major Industrial Ethernet protocols globally, while Profibus is the leading fieldbus. Both Industrial Ethernet and Wireless is growing.

Communication solutions can reduce energy usage and minimize downtime in food and beverage plants substantially. By monitoring temperatures, levels, running hours etc. you can make sure you don’t use more resources than necessary and also safeguard the health of your food and beverage machinery. Avoiding production stops and costly downtime.

Strong OT Cybersecurity is a central element for the digitalization of any food or beverage production plant.

Ewon solutions from HMS are certified according IEC 62443 and ISO 27001 standards. This remote access solution implements the latest security technology to secure production from external threats.

Also, HMS network diagnostics tools spot external and internal security threats within production lines.

Have a communication expert from HMS contact you to discuss your specific requirements.