White papers

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

A Chinese manufacturer has set a new benchmark in conveyor belt systems with high speed, flexibility, and precision. They integrated Ixxat INpact multi-protocol PC interfaces to ensure compatibility with various industrial communication protocols.

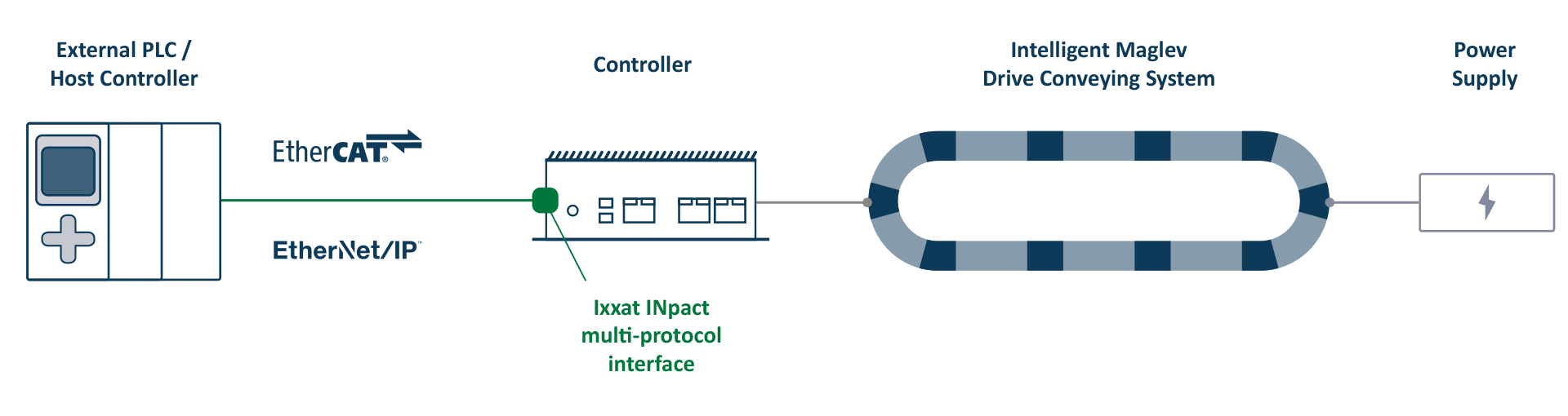

With a repetitive positioning precision of 5 µm, a maximum speed of up to 5 m/s and a support of maximum 256 movers at the same time, a Chinese manufacturer of cutting-edge conveyor belt systems sets a new benchmark in terms of speed, flexibility and user-friendliness. To ensure these benefits, the magnetic conveyor systems need to be integrated into state-of-the-art communication systems of existing customers. Faced with the challenge of ensuring compatibility with multiple industrial communication protocols, they turned to the Ixxat INpact multi-protocol PC interface series from HMS Networks to power their solutions. By having them implemented in their controller system, the system easily gets EtherNet/IPTM, EtherCAT or PROFINET signals turned into the proprietary ethernet of the conveyor system and vice versa.

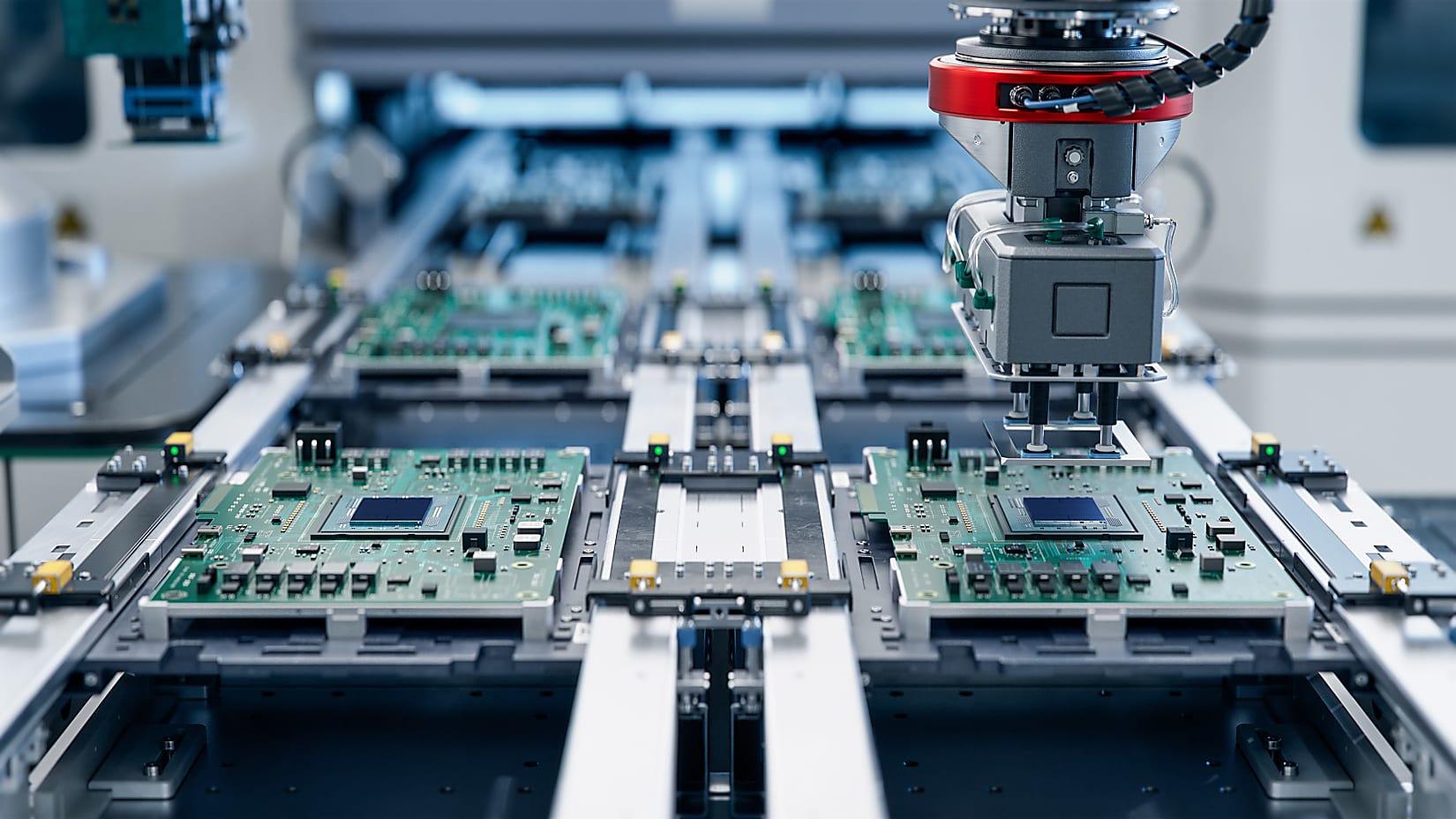

The manufacturer’s intelligent conveying systems are used in high-end manufacturing sectors such as 3C (computers, communication and consumer electronics), lithium battery production as well as semiconductor production or packaging equipment amongst others. These industries require fast, flexible and reliable conveyor systems. The customer’s specific challenge stemmed from the need to expand their magnetic drive controller’s communication capabilities to include support for EtherCAT, EtherNet/IPTM and PROFINET protocols. Additionally, the system had to ensure stable communication between various PLCs (programmable logic controllers), which are given on the customer side, and the proprietary Ethernet interface used in the conveying system.

The company was using an X86 industrial PC (IPC) platform for their control unit. To adapt to the diverse needs of their industrial customers, they needed a communication interface that could handle multiple protocols without requiring extensive redevelopment and a huge implementation effort. Furthermore, ensuring the long-term stability and reliability of the solution was crucial to maintain smooth operations in high-speed, high-demand manufacturing environments.

To address these challenges, the Ixxat INpact CE Slave PCIe Mini Kit was selected. This versatile solution provides multi-protocol communication capabilities, including support for EtherCAT, EtherNet/IPTM and PROFINET among others. The INpact interface allows the conveyor’s magnetic drive controller to seamlessly interact with various external PLCs, enabling data exchange via a proprietary Ethernet line between the controller and the conveyor belt.

The INpact solution proved to be ideal for this application due to its flexibility, ease of integration, and compatibility with multiple communication protocols. With minimal development time, the manufacturer was able to adapt their system to meet the diverse communication requirements of their clients. The Ixxat interface also ensured the stability and reliability of the communication, which was essential for the continuous operation of the conveyors in high-end manufacturing environments.

The Ixxat INpact CE Slave/PCIe Mini Kit is a multi-network PC interface designed to provide real-time communication across multiple industrial protocols. For this project, the product enabled communication between the magnetic controller and various PLCs. The INpact interface converts the data from external PLCs (using EtherCAT, EtherNet/IPTM, or PROFINET protocols) into a format that can be processed by the controller. From there, the controller communicates with the conveyor system via a proprietary Ethernet connection, ensuring precise control and monitoring of the conveyor’s operations.

Key features of the INpact series include its compatibility with multiple industrial protocols, a compact PCIe mini form factor ideal for space-constrained applications, and robust support for Linux systems, which was critical for this application. These features allowed the Chinese manufacturer to integrate the solution without major modifications to their existing infrastructure, streamlining the development process.

Country: China

Solution: PC interface for reliable multi-protocol communication

Industry: Intralogistics

Product: Ixxat INpact

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Our products solve everyday industrial communication problems. Discover how our customers have improved their business with HMS case studies.

HMS communication solutions help thousands of companies solve specific communication problems in many different industries and applications.