Q&A

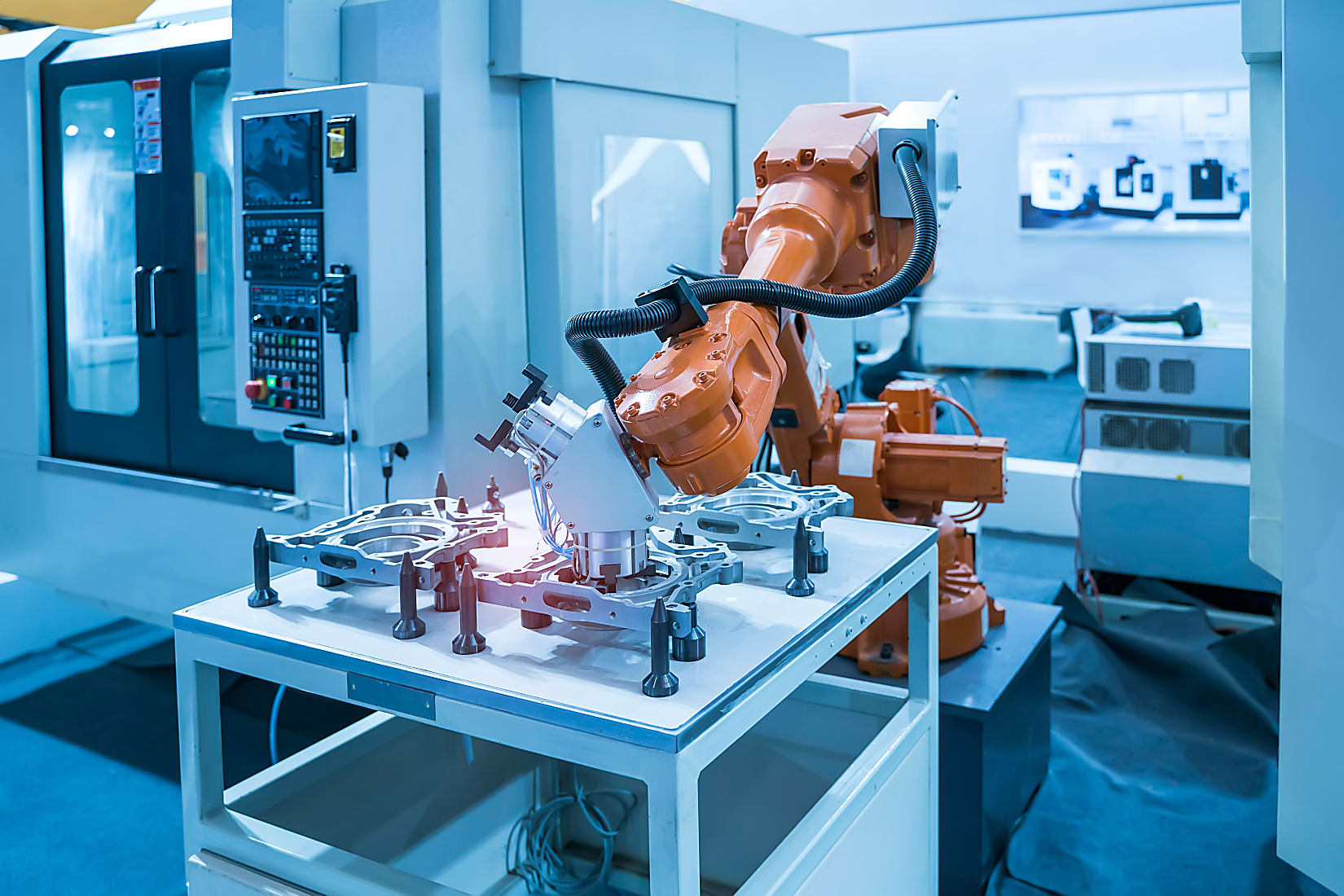

What is communication for Factory Automation?

Communication is key for a well-functioning factory. PLC systems from an older part of the factory need to communicate with a newer part. Machines need to be accessed remotely, New machines need to be integrated. And the entire factory network needs to be monitored and failsafe. HMS offers communication for factory automation solutions to solve these issues.

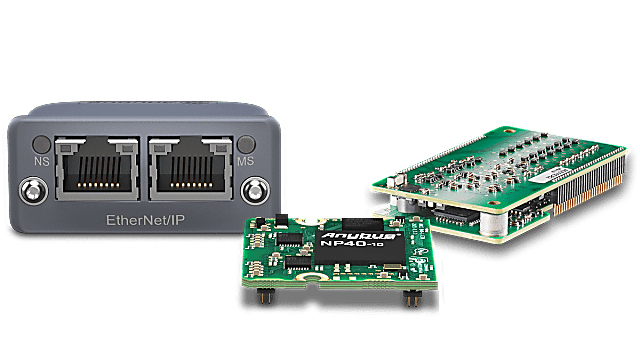

Which are the most common networks in Factory Automation?

According to HMS research, PROFINET and EtherNet/IP share first place when it comes to new installed nodes within Factory Automation, both with 18% market share followed by EtherCAT at 12%. Industrial wireless is also growing rapidly with 8% of the market, while fieldbuses like PROFIBUS and Modbus-RTU are declining. Due to the large installed base, there are still many Factory Automation machines using fieldbuses.

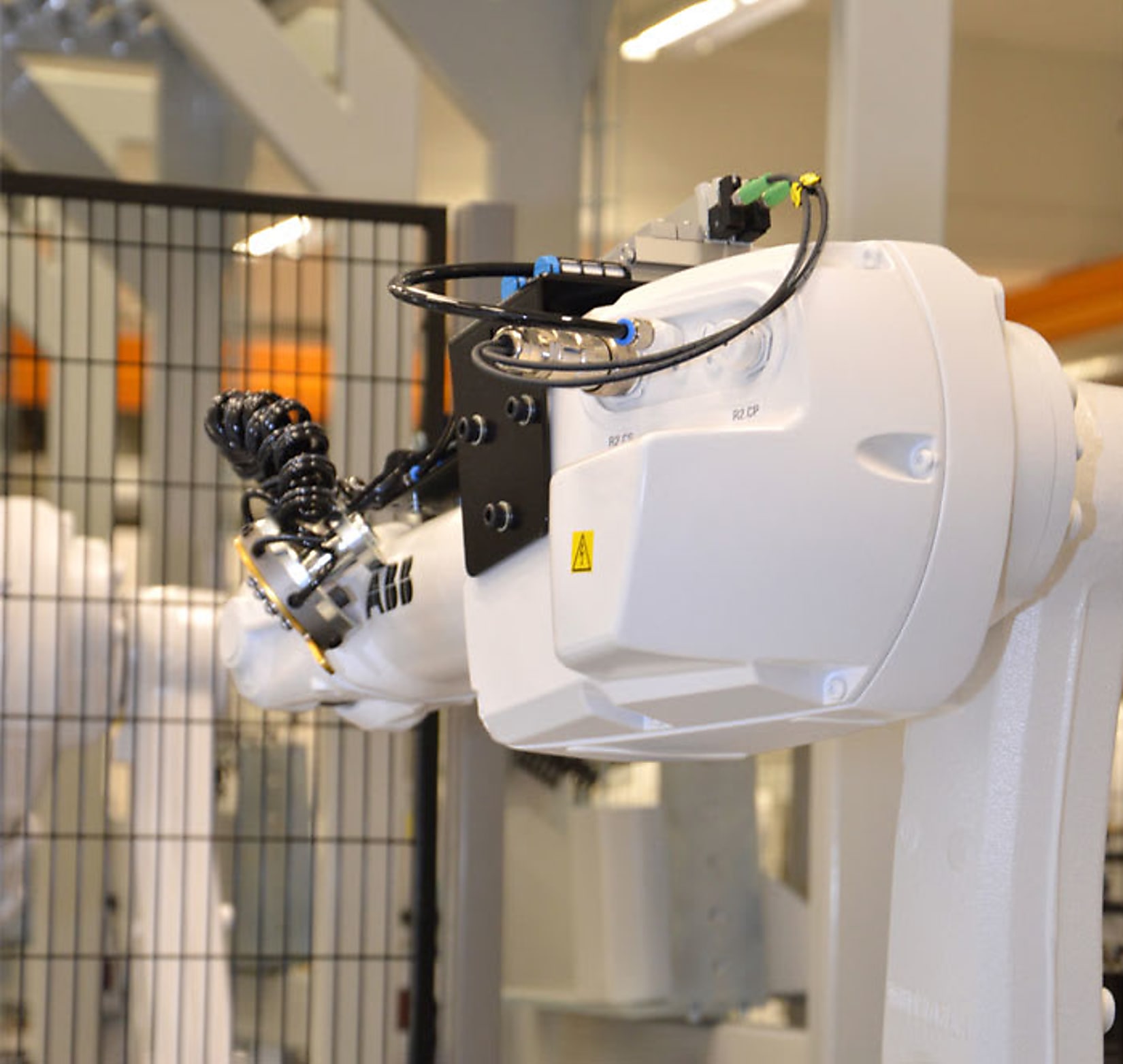

How can I do remote access for Factory Automation?

With Ewon Remote solutions from HMS Networks, it is possible to remotely access PLC-based machines to do troubleshooting and maintenance from anywhere. The remote solutions are secure and penetration-tested and enables quick access to machines with a laptop or tablet, just like being on site.