Process automation solutions

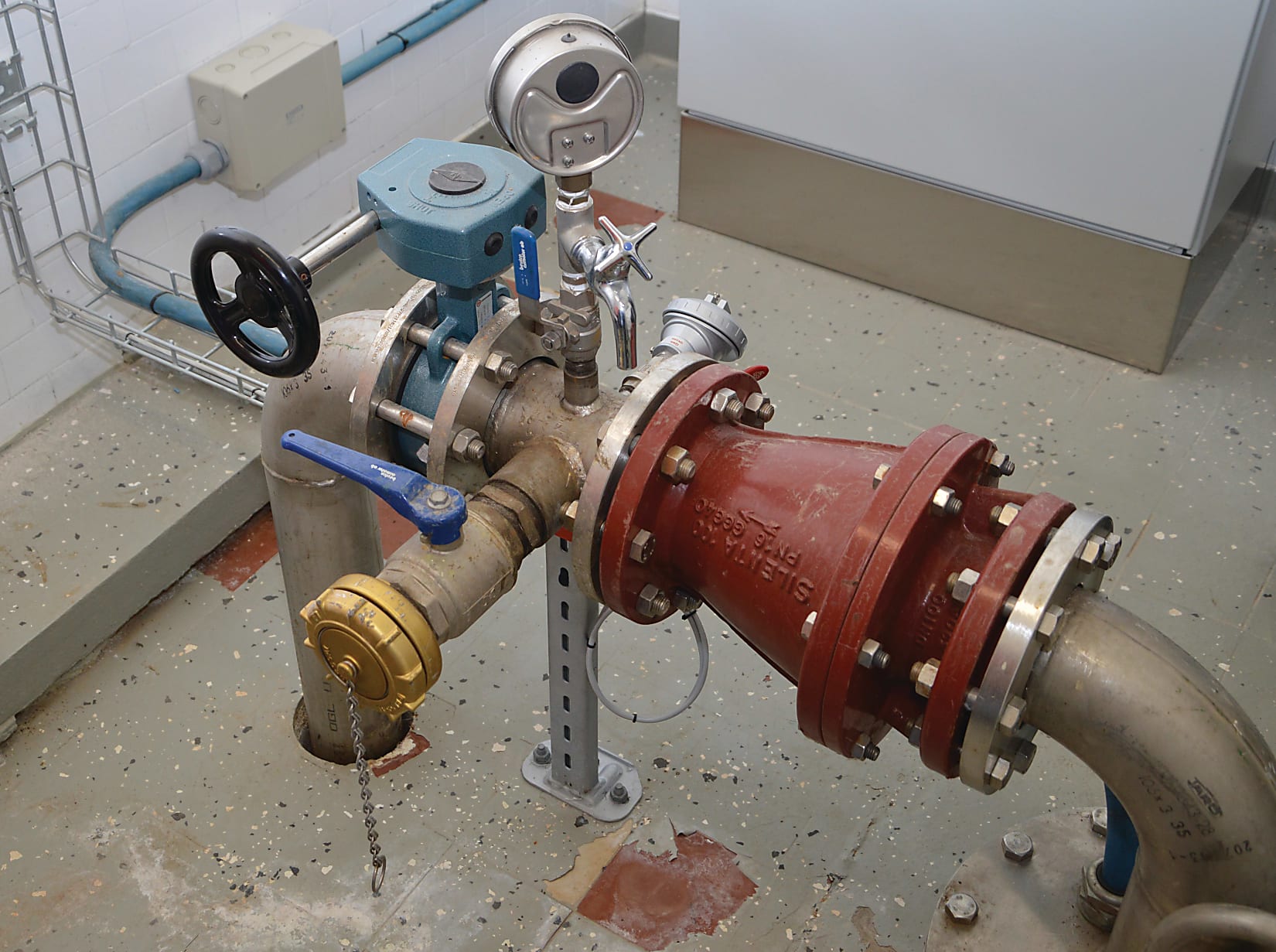

Want to connect an older part of a processing plant to a newer system? Or embed network connectivity into an industrial device?

Anybus solutions from HMS Networks connect any device to any network.

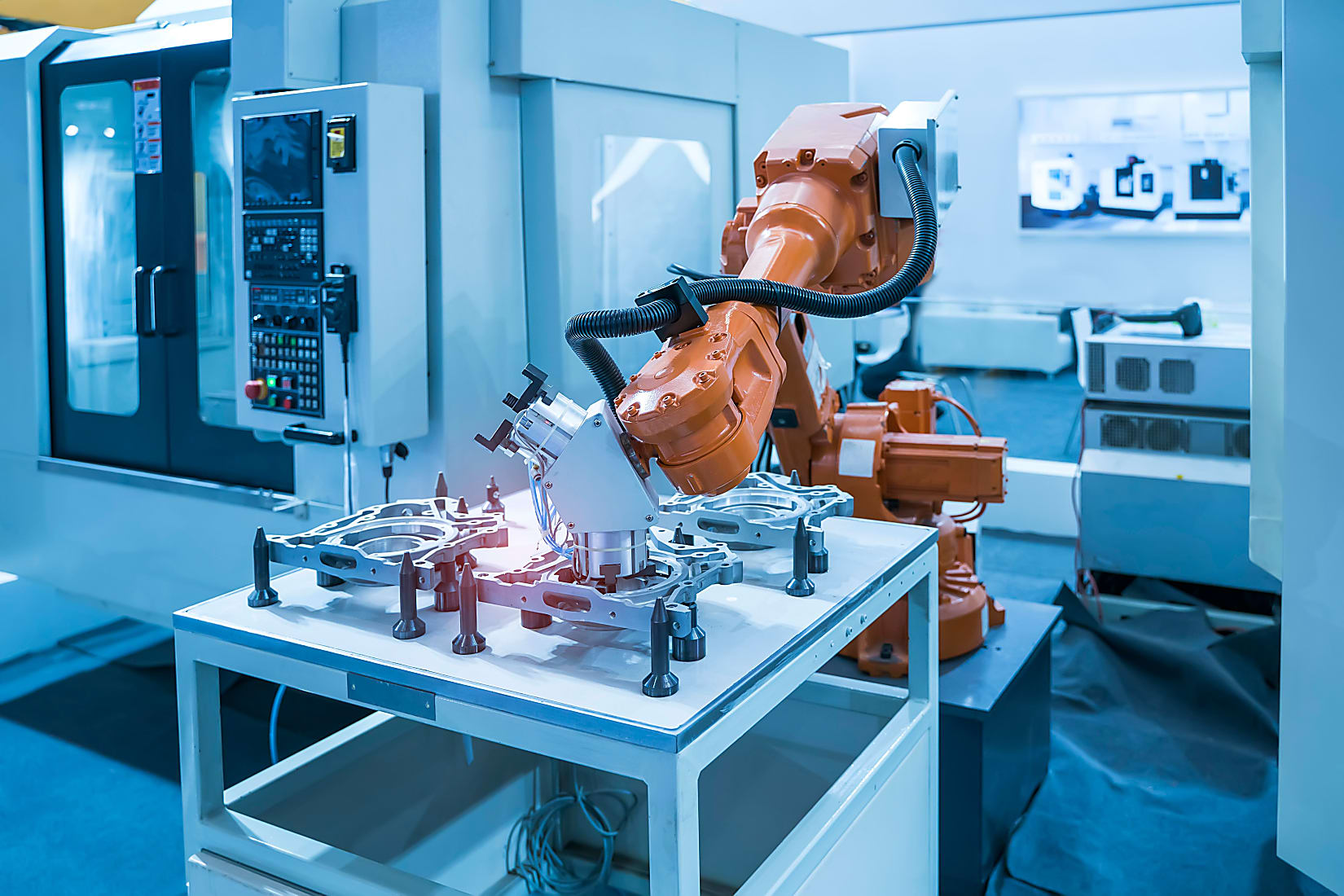

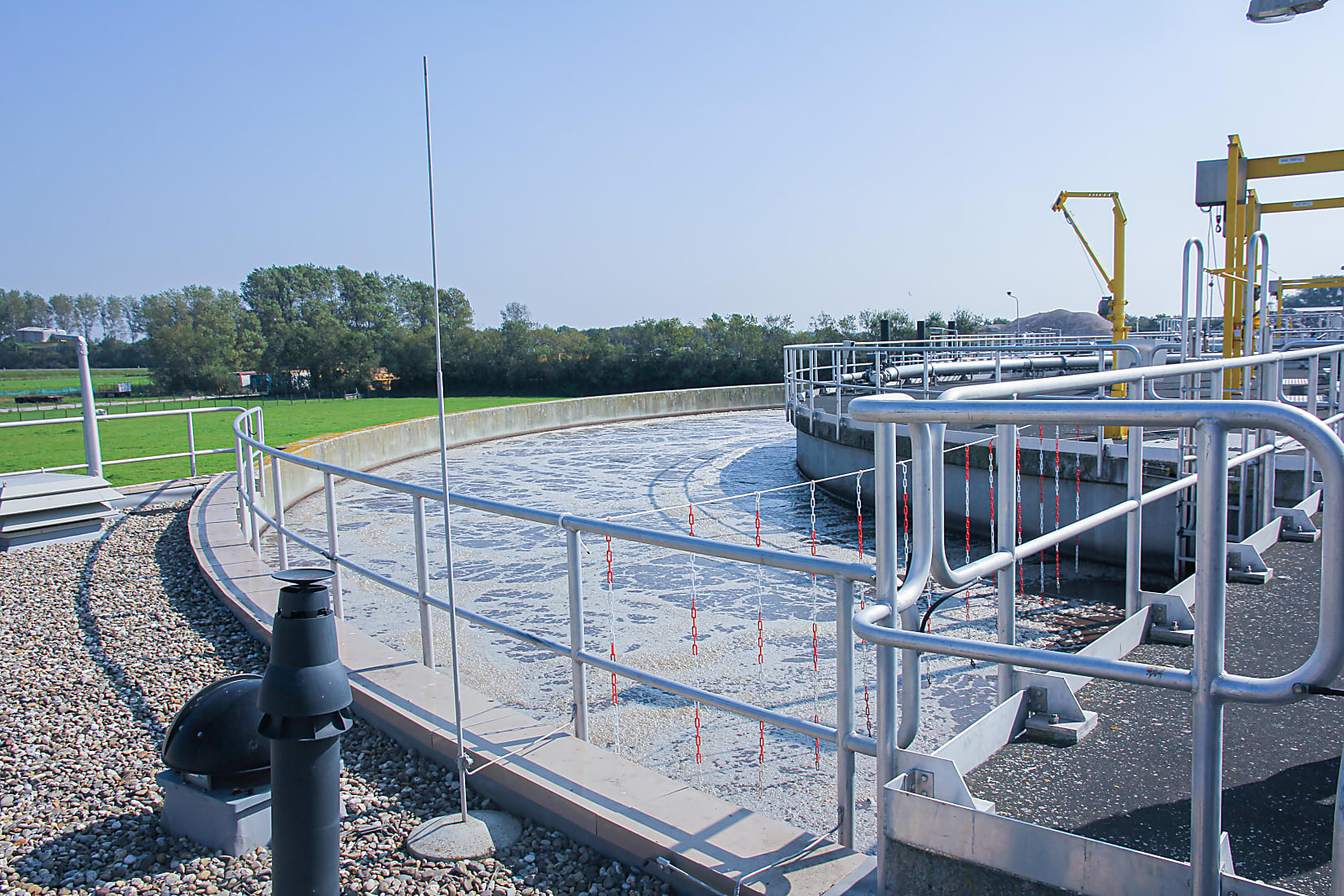

Pumps, conveyor belts, sensors, actuators, controllers—most industrial devices in process automation plants are connected. HMS enables seamless communication across fieldbuses and industrial Ethernet, while also delivering real-time data visibility, simplified integration, secure connectivity, and reliable performance from the edge to the enterprise.

Want to connect an older part of a processing plant to a newer system? Or embed network connectivity into an industrial device?

Anybus solutions from HMS Networks connect any device to any network.

HMS may also help you with network diagnostics in process automation — health checks, reports and best paths of repair for industrial networks – all to avoid costly downtime.

It includes permanent monitoring and troubleshooting solutions as well as services, training and tools for more robust infrastructure.

Ewon remote connectivity solutions allow you to connect to industrial equipment from anywhere for maintenance and troubleshooting. These solutions use industrial VPN gateways and a secure cloud to log, visualize and analyze equipment data.

Visualized dashboards make it easy to monitor even the most complex industrial processes remotely and enable quick optimizations. The end result? Enhanced overall productivity!

CAN and CANopen are the communication backbone of many industrial machines. HMS Ixxat products enable CAN communication such as PC connectivity, CAN line extension, bridges, gateways and much more.

Moving machinery in a process plant needs to operate in a safe way to avoid damage. But connecting to safety networks such as CIP Safety, PROFIsafe and FSoE is complex and time-consuming.

Ixxat Safe from HMS Networks offers the industry‘s most comprehensive product and service offerings for integrating safe IOs and communication solutions based on EN ISO 13849-1 and EN/IEC 62061.

Get rid of the cables! Connect machines and devices via Bluetooth, Wi-Fi, or cellular wireless (3G/4G/5G) to create wireless bridges or access machine data.

Got 5G?

Want to evaluate 5G in your plant? HMS offers 5G routers and starter kits allowing you to implement and test 5G in your site.

Red Lion’s Crimson configuration software empowers process automation professionals to take control of their industrial systems with ease. From a single, user-friendly platform, you can rapidly configure Red Lion HMIs and edge devices, integrate with a wide array of industrial equipment, and securely access critical data in real time. Crimson simplifies complex tasks—so you can focus on optimizing performance and driving results.

N-Tron’s rugged, industrial-grade design and environmental ratings make it ideal for deployment in even the harshest conditions. Whether you need managed or unmanaged switches, N-Tron offers a wide range of port configurations to meet your specific networking requirements. With an intuitive web-based GUI and robust security features, N-Tron delivers reliable, secure Ethernet connectivity making it the smart choice for mission-critical industrial applications.

Communication is key for a well-functioning plant. PLC systems from an older part of the factory need to communicate with a newer part. Machines need to be accessed remotely. New machines need to be integrated. And the entire factory network needs to be monitored and failsafe. HMS offers communication solutions to solve these issues.

With Ewon Remote solutions from HMS Networks, it is possible to remotely access PLC-based machines to do troubleshooting and maintenance from anywhere. The remote solutions are secure and penetration-tested and enables quick access to machines with a laptop or tablet, just like being on site.

Have a communication expert from HMS contact you to discuss your specific requirements.