White papers

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

WES uses the Ewon Flexy 205 combined with i4connected to establish an remote monitoring system for their global wind turbine fleet. The Flexy 205 enables secure VPN connections, data extraction from turbine PLCs, and data exchange with i4connected for remote monitoring and analysis.

Wind Energy Solutions (WES) is the global leader in the growing market for midsize wind turbines and has 40 years of proven technological experience. Located in the Netherlands, they manufacture the WES50, WES80, WES100 and WES250 midsize wind turbines. These accessible, affordable turbines are distributed around the world through a global network of trained and certified partners.

WES has a large and varied customer and location base (large farms, remote businesses, etc.) and is present even in areas where supply can be problematic. Their turbines offer users around the world lower energy costs and lower carbon emissions.

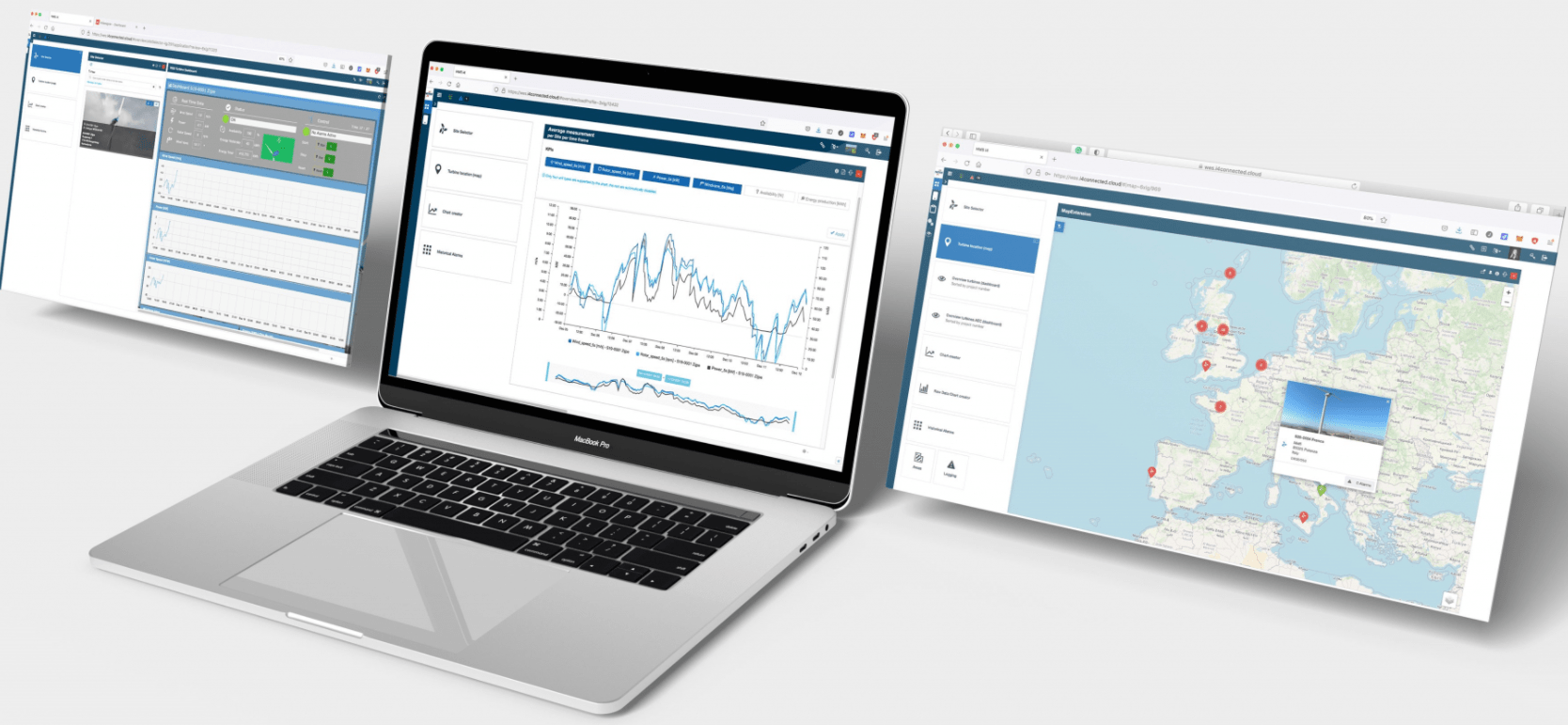

In order to connect and monitor their equipment, WES chose solutions from HMS Networks. They decided to implement the Ewon Flexy 205 inside the control panel of their wind turbines. WES’ first and main objective in using Ewon’s industrial gateway is to be able to establish a secure VPN connection to the equipment from their own offices, for remote maintenance purposes. Secondly, WES uses the Ewon Flexy as a crucial element in their new data-service to optimize turbines’ efficiency and uptime. They do so by extracting relevant data (wind speed, energy production, rotation speed, etc.) locally from the wind turbine’s PLC. This data is used for monitoring and control (start, stop, reset) of the equipment. Finally, WES uses the Ewon Flexy to exchange data via secure MQTT protocol with the cloud platform i4connected. This third function allows WES’ customers to remotely monitor their own turbine via the Internet and to analyze performance over the long term.

WES uses the the Ewon Flexy 205 and i4connected to monitor important KPIs (windspeed, power output, rotation speed etc.) and control (start, stop, or reset) PLC and power conversion hardware.

"In the summer of 2021, we launched our new control system based on i4connected. We set it up thanks to the integration of the Ewon Flexy industrial gateway from HMS Networks", explains Lars Koel, Service Engineer at WES. "Turbine owners can easily remotely access their turbines and get up-to-date information on their status and performance. This system also allows the turbine to be remotely operated in complete safety. Wind turbine owners automatically receive monthly reports on performance and conditions such as power delivered and measured speed."

Turbine owners can easily get up-to-date information on the status and performance of their turbines. This system allows the turbines to be remotely operated in complete safety.

Lars Koel, Service Engineer, Wind Energy Solutions (WES)

Using the latest technologies in the data infrastructure and visualization areas, WES has established a system where their turbine fleet can be started, reset, stopped and optimized remotely by turbine owners. This can be done from anywhere in the world, on a computer, cell phone or tablet. WES’ system was developed to be as simple as possible by displaying straightforward and easy to understand dashboards.

On top of that, the combination of an Ewon Flexy and i4connected IIoT platform gives WES’ end users 24/7 insights through WES SCADA, which is perfect for condition monitoring. Advanced performance information (such as Detailed Energy Production, Power Curve and Turbine Data) is graphically presented to provide the best possible overview. WES clients are then able to optimize turbine parameters based on accurate on-site conditions to achieve maximum efficiency. All data reports and graphs can easily be downloaded and exported.

The HMS offer stood out in the eyes of WES because it provided a complete solution, combining three pillars: remote access, remote monitoring and data visualization. In addition, this comprehensive solution turned out to be perfectly scalable and cost-effective.

WES has enjoyed many advantages by using Ewon and i4connected combined solution: travel (and so cost) reduction, real-time centralized insights on turbine fleet, easy remote control,... All of these can be summed up in one simple word: convenience.

Another big plus for WES is the «wow» factor when selling, as this integrated solution makes it possible to offer modern value-added data services to users. It generates new revenue streams for WES, as well as giving them a competitive advantage.

As we can see, harnessing field data can create tremendous value for both machine builders and end-users. Ultimately, choosing to implement a professional secure remote connectivity solution is a path that benefits everyone involved.

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Our products solve everyday industrial communication problems. Discover how our customers have improved their business with HMS case studies.

HMS communication solutions help thousands of companies solve specific communication problems in many different industries and applications.