White papers

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

A comprehensive look at the challenges, solutions, and successes in implementing essential safety features for the European market, facilitated by a partnership with HMS Networks.

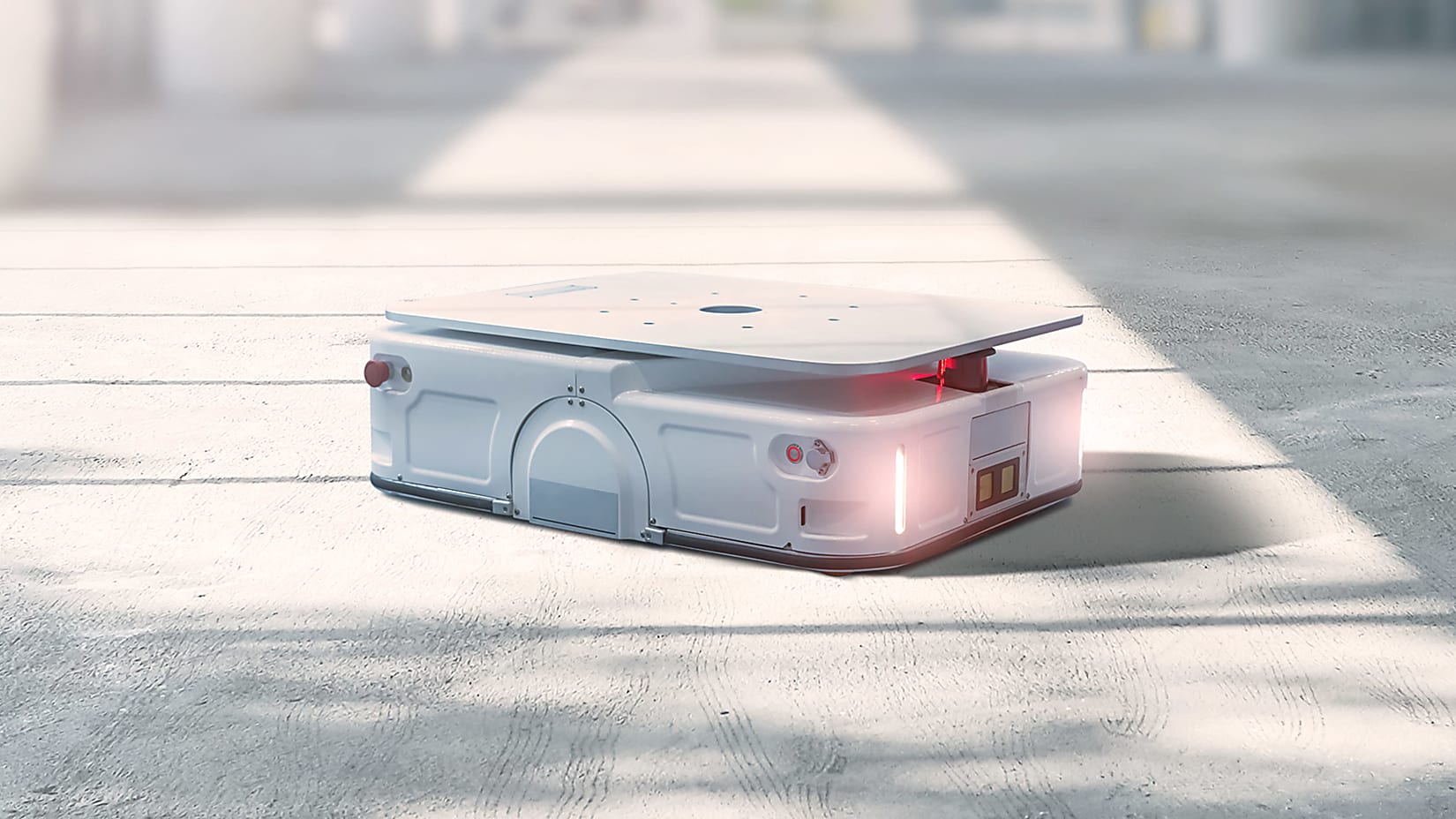

Around the world, automation in logistic applications is becoming commonplace. Most manufacturers of logistic automation vehicles – Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) – are found in China, Europe, and America. While these regions are also the main application markets, the cross-regional export and import of these machines present challenges, with regions having their own distinct regulations for AGV and AMR import and operation.

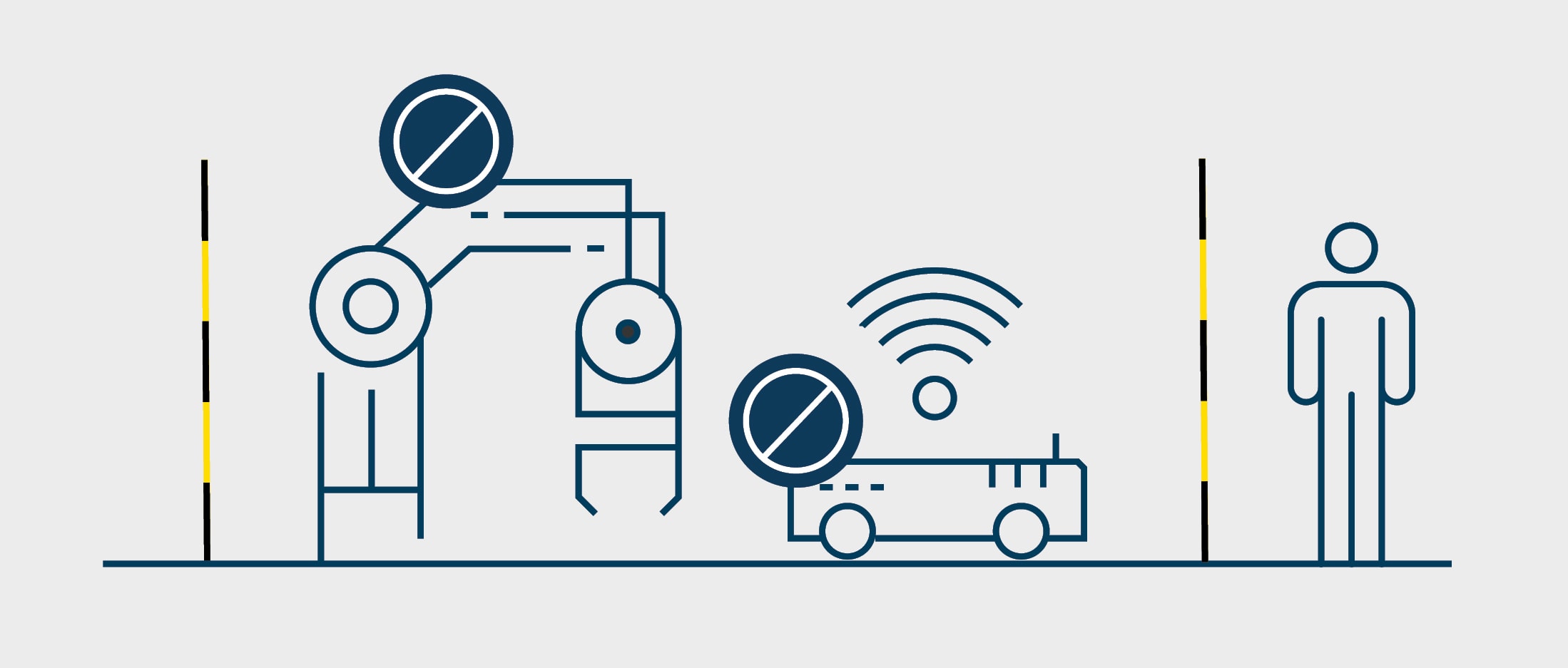

Safety implementation: When robots and AGVs are in operation, safety fences with safely interlocked doors must be used to prevent human operators entering the operational area. When a human operator enters the danger zone, all movements must be stopped. Once the operator has left the fenced area, and confirmed that it is safe and clear, the robot and the AGV will receive a signal to resume operation.

A leading Chinese AMR manufacturer faced these challenges when it needed to meet specific safety functions required by a European end-customer. Although it was adept at serving the needs of its domestic market, it found difficulties in meeting European safety standards, as the demand for safety functions in machines differs significantly.

As an AMR manufacturer and integrator, partnering with HMS Networks brings numerous benefits. Firstly, we can achieve a high level of safety, easily meeting performance level (PL) d, ensuring the reliable operation of our AMRs. The modular solution is incredibly user-friendly, saving us time during development. What’s more, the pre-certification of the Ixxat Safe T100 module by TÜV Rheinland simplified our certification process immensely, allowing us to bring our products to market faster.

Stated by our chinese AMR customer

To penetrate the European market, European end-users demanded safety functions, such as the ability to safely stop the AMR remotely in compliance with local worker and environmental safety laws. Given the rapid growth in the logistic automation sector and intense competition from European manufacturers, a swift and efficient solution was crucial.

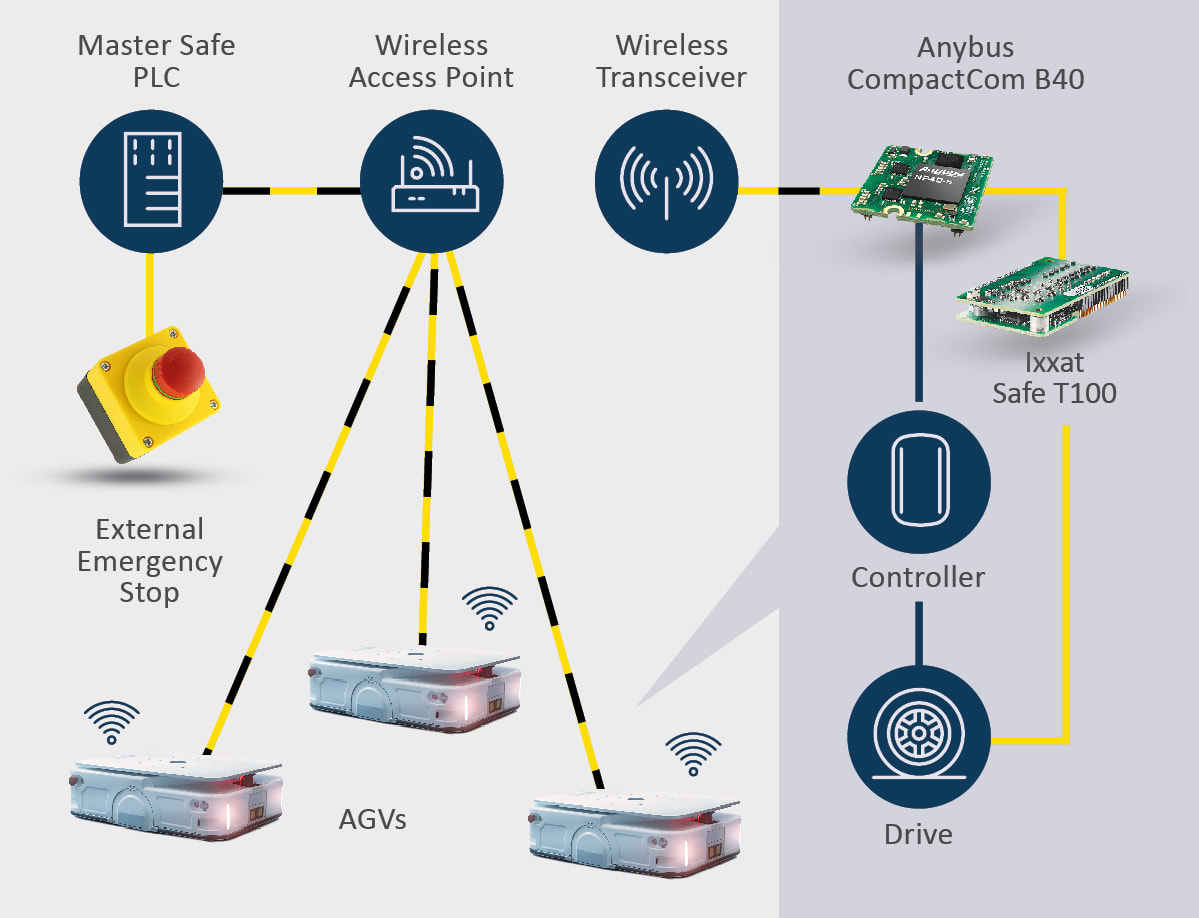

Our customer’s initial step was to implement EtherNet/IP – a standardized non-safe communication protocol – into the AMR controller. The next step of safety implementation involved the CIP Safety protocol and connecting it to the drive’s existing safe stop inputs.

HMS played a pivotal role in aiding the AMR manufacturer, negating the need for it to become an expert in foreign safety protocols and standards as well as in general functional safety implementation. Furthermore, the versatility of HMS’s communication modules ensures rapid protocol switching. For instance, if European end-customers desire to automate their AMR fleet using Siemens PLCs, the CompactCom and T100 modules can easily be switched to the ones supporting the requested protocol, like Siemens PROFInet/Profisafe, without major hardware redesigns.

This flexibility reduces costs and speeds up the introduction of a new AMR family into a different market segment. An additional advantage for the customer was the unparalleled sales and technical support provided by HMS China, spanning basic purchasing inquiries to assistance with the safety certification process. With the combination of the Anybus CompactCom and the T100, it found the perfect solution for integrating these required safety functions. The CompactCom and T100, with their compact sizes and adaptable integration capabilities, allowed the seamless incorporation of both safe and non-safe communication into the AMR. This addition, combined with the pre-certified solutions from HMS, enabled the manufacturer to design the requisite safety functions in just 10 months, including TÜV certification.

With the new machinery regulations in the European Union 2027, the safe remote stop of AGVs/AMRs will become a requisite feature. The transition period and the fact that the regulation will solely affect EU countries means many manufacturers, including those in China and the US, might not be fully prepared for the imminent safety standards.

While not all end-customers currently demand specific functions at their safety implementation, it’s imperative for AGV/AMR manufacturers to be agile in responding to market needs. HMS’s safe and non-safe technology offers an easily integratable solution that paves the way for a swift safe-remote-stop market entry.

Country: China

Solution: Ixxat functional safety

Industries: Industrial automation / AMRs and AGVs

Products: Ixxat Safe T100 and Anybus CompactCom B40

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Our products solve everyday industrial communication problems. Discover how our customers have improved their business with HMS case studies.

HMS communication solutions help thousands of companies solve specific communication problems in many different industries and applications.