White papers

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

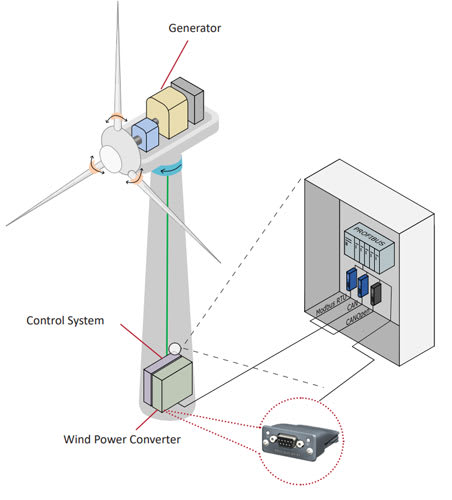

Through Anybus solutions, wind power converters can be seamlessly connected to the main control system.

This is a real-life case study, however, the customer has chosen not to feature their brand name.

A wind turbine is like a small, automated factory with an advanced control system. The main control system needs to communicate with operational systems in the turbine such as yaw and pitch systems in order to realize the efficient transformation from wind to electric power. One of the most important parts in the turbine is the current converter system which needs to be operating reliably in order to deliver a smooth flow of electricity. Through Anybus embedded and gateway solutions, wind power converters can be seamlessly connected to the main control system.

Our wind turbines are mostly installed at harsh environments like high mountains far away from the closest city. We need to make sure the systems run smoothly and reliably, because once there is a failure or shutdown, it results in huge losses. The high performance and high stability of Anybus products in harsh environments and the excellent service of the HMS team make us feel safe."

The wind turbine uses wind to turn the rotor blades of the windmill converting wind energy into mechanical energy. The mechanical energy is then converted into electricity by a generator in the nacelle*. The voltage generated by the wind turbine is 690V AC after the converter, which is increased to 35kV by the transformer next to the tower. The combined power from several wind turbines are converged into a collecting wire and sent to the substation through the overhead transmission line. The substation converts the voltage to 110kV or higher and delivers it to the power grid.

Wind power converters are mainly used together with generators. The main function is to reach the same amplitude, frequency and phase of the output voltage on the stator (non-moving) section of the generator as the power grid. The goal is to achieve VSCF (Variable Speed Constant Frequency), get the best power generation efficiency and quality, thus improving energy efficiency. Therefore, the controller inside the converter needs to communicate with the main controller, and quickly and securely send the data to the main controller of the generator set, so it can set the control command to the converter in time.

After comparing and testing several different solutions, the customer finally selected the Anybus Wireless product from HMS. They installed an Anybus Wireless Bolt on each RGV, together with the on-board PLC. The Anybus Wireless Bolt is connected to the PLC via an Ethernet cable and then connected to access points via WiFi. The access points communicate with the main control PLC, enabling control of the stage lights.

The company uses Anybus solutions to achieve seamless communication with the main control PLC system.

“Most of our converters use CAN or CANopen interfaces. If the main controller also uses CAN/CANopen to communicate, it is not a problem, but many main controllers are from Siemens and use PROFIBUS DP or PROFINET to communicate, which raises a problem,” the customer mentioned.

“If we were to develop different protocols one by one with dedicated chips or protocol stacks, it would take a long time, and we also need to pay attention to research & development risks, testing and certification issues, not to mention the fact that people are getting used to the stable operation of our products in the field, so we really don’t want to make any changes to current hardware and software of the converters.”

After a comprehensive comparison, the converter manufacturer chose Anybus from HMS Networks. The Anybus offering has both plug-and-play embedded products, as well as stand-alone gateways and provides the customer with flexible choices to achieve seamless communication with the main control PLC system.

“Our wind turbines are mostly installed at harsh environments like high mountains far away from the closest city. We need to make sure the systems run smoothly and reliably, because once there is a failure or shutdown, it results in huge losses. The high performance and high stability of Anybus products in harsh environments and the excellent service of the HMS team make us feel safe. ”

A combination of Anybus products to solve the communication problem of the wind power converter: Anybus Embedded and Anybus Gateways.

The customer’s wind power converters have used thousands of Anybus embedded modules and Anybus Communicator gateways. They have now also chosen embedded Anybus chips (C40) as the key communication solution in their drives. Currently, the products are already on the market and continue to grow at a high speed.

Solution: Network connectivity

Industries: Wind power

Products: Anybus CompactCom and Communicator

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Our products solve everyday industrial communication problems. Discover how our customers have improved their business with HMS case studies.

HMS communication solutions help thousands of companies solve specific communication problems in many different industries and applications.