Sure, Routeco has its headquarters in Milton Keynes, England, but we’ve now expanded and have offices throughout Europe. We specialize in the distribution and integration of industrial automation and control products in various industries, including manufacturing, utilities, and transportation.

Our customer was a large company based in Gateshead in the north of England. They work with all sorts of things, but this example was related to automation, and in particular measuring water quality. They have hundreds of environmental sensors measuring water quality, some of which are collecting hundreds of different measurements. So, there’s a lot of data.

They wanted to connect various sensors with different serial protocols to a Schneider PLC, and they also wanted to use an extended baud rate. In short, they needed a fairly powerful protocol converter.

Yeah, exactly. I suggested the Anybus Communicator as I knew it could interpret these protocols and offer a baud rate of 1200 bps to 128 kbps.

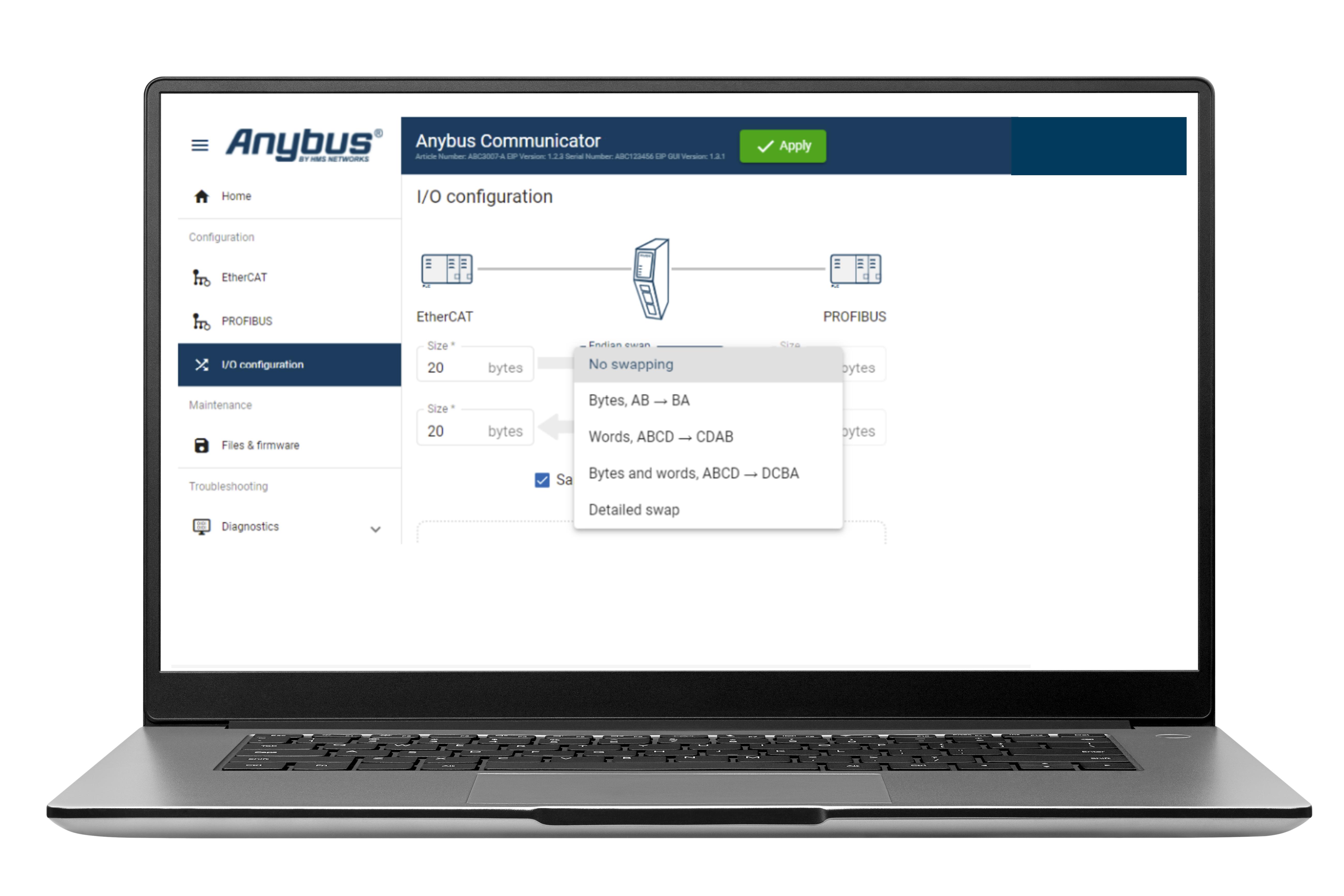

The byte swap feature is a really good feature. It’s made an enormous difference because it cuts out all the programming needs. Before, it was a real hindrance to people adopting it as they had to write some more software and mess about with the data. Now, the byte swap has taken away all those objections, making the installation a lot easier.

The dedicated Ethernet configuration point made life easier. The first time I used the older gateways, I lost the specific configuration cable and had to ask HMS to send a replacement. The fact that we didn’t need to use a special cable made everything a lot easier. With the newer Communicator, we were straight in as soon as I got the device. After a quick look at the manual and downloading the new firmware and we were up and running.

The wired serial port or serial cable connector was also useful. We were using a loan piece of kit, so the customer didn't want to solder D-type connectors onto it. Instead, we were able to use a screw terminal detach adapter, which saved a whole load of hassle.

I looked at the emulator while waiting for the Anybus Communicator to arrive, just to see how it was going to look and how to use it. I shared this with the customer, and he was over the moon, as it provided reassurance that the Anybus Communicator was going to be able to do what was needed.

Yes, I very rarely had to look at the manual. After I helped our customer set up a bench test, I haven’t heard from him. Usually, customers will call to ask about each application, but this time, nothing - suggesting that the Communicator has been easy to use. Otherwise, they’d be on the phone!

Haha, true. We didn’t have any troubleshooting issues in this case, but we have used the HMS troubleshooting process previously and we’ve always received excellent support. It’s one of the things we like about HMS and Anybus. The support is quick too. I’ve logged issues at 6pm and I’ve got an answer when I log in in the morning.

Pleasure!

Take our user interface for a spin

Find our new range of gateways