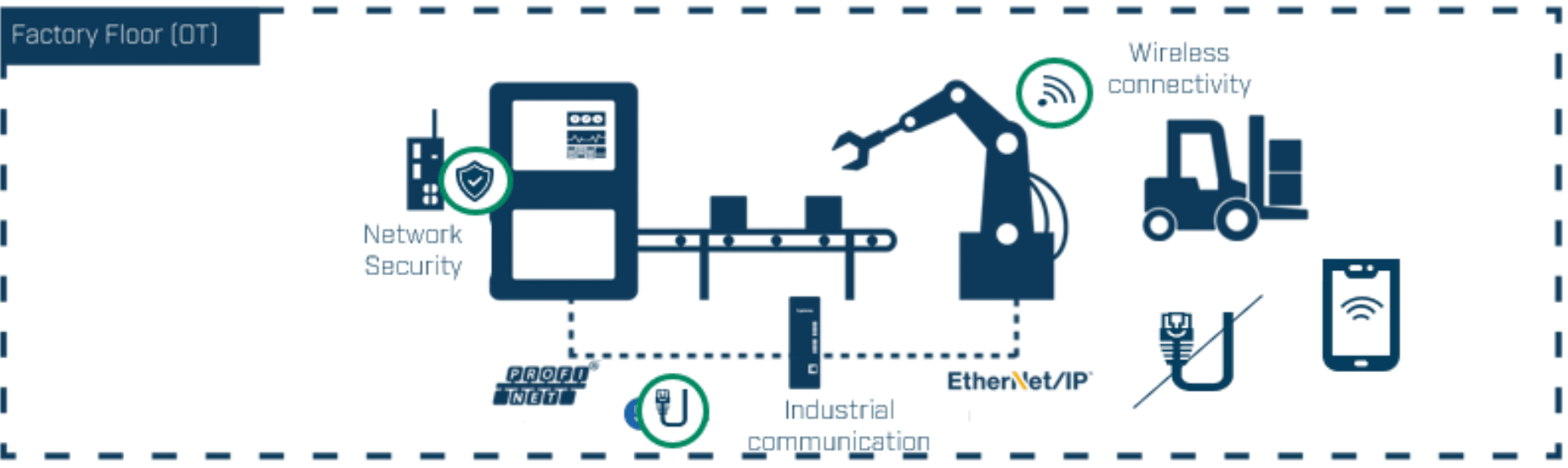

Connect, communicate, and secure

The quest for efficiency, seamless integration, and robust security in machinery is more critical than ever. Innovative tools like Anybus communication solutions are helping automation engineers address the future of machinery by enabling seamless connectivity, enhancing communication, and fortifying security.

The communication challenge

Modern machinery often operates as part of a complex industrial ecosystem. Connecting and synchronizing this production equipment is key to gaining more visibility and optimizing the production flow.

The global reach of many industrial manufacturers means machines must adapt to varying regional communication standards and technologies. This diversity of markets, applications, and customer communication requirements adds layers of complexity and present a challenge for automation engineers.

Many companies lack in-house expertise in communication and network expertise, which can impede the integration of machines into any industrial networks. Each new technology introduces new challenges and learning curves. Network and communication planning differs between technologies and often leads to misconfiguration, impacting machine efficiency sometimes only after several years or after the next evolution.

HMS Networks: connect Any Device, Any Network

Working with an expert like HMS Networks ensures that automation engineers receive communication solutions to interface any industrial network efficiently. The intuitive user interfaces and protocol-neutral approach of our products simplify the transition for users to any required technology

With HMS Networks’ long-standing market presence and extensive experience, we guarantee the use of proven and reliable solutions installed in millions of units across a wide range of industrial applications globally.

Case Study 1: Integrate your machine in any PLC Network

Smaller machines, like compressors and generators, often run autonomously on the plant floor. These machines are typically based on compact and specific controller units, usually using a unique communication protocol such as Modbus or EtherCAT.

Integrating these units into a global operations infrastructure allows operation managers to have stronger control over these assets. These machines can now operate connected with the production line, allowing for anticipated maintenance issues and optimized efficiency.

This means machine manufacturers require support for multiple communication technologies when sold across different regions, creating significant hurdles for automation engineers.

Time to market and customized interfaces

Anybus Gateways connect the internal machine controller to any external industrial protocol.

This ready to use and certified solution eliminates the need for intricate development projects and reduces the risk associated with integrating and maintaining multiple networks. Only a few configuration parameters are required to define the machine data to exchange and the PLC communication technology to use for sharing it.

With an easy, intuitive graphical interface, even non-network experts can quickly complete these steps. Optionally, HMS can customize the gateway with pre-configured settings and branding. This further simplifies installation and allows machine builders to make the gateway look like one of their own products.

Case study | Automating the impossible in any factory, in any country. Explore how Bosch Rexroth combined the Anybus Communicator with their Smart Flex Effector to bring industrial automation's most versatile compensation module to the world. |

Range of gateways

| |

User interface | Explore The easiest gateway configuration tool you have ever seen! |

Case Study 2: Machine flexibility and modularization

Larger machines often consist of smaller modular units, each with distinct functions. For example, liquid filling machines include blowing, filling, capping, and labeling modules, among others. The ability to interconnect these modules seamlessly without compromising performance and reliability is crucial for efficient machine design, validation, and flexible installations in factories.

Network security with real-time data

Anybus Gateways enable this machine network segmentation by bridging two independent machine networks of the same or different communication standards. The data transfer between the two sides happens within a millisecond, supporting high-performance applications, while the compact design of the gateways allows for cost-effective installation.

The gateway offers robust security features, including a security hardware chip, signed firmware, and configuration locks. This ensures that each machine communication interface remains secure against any external cybersecurity threats.

By creating this electrical, communication and security separation, these gateways protect internal machine networks by strictly segmenting them. This independence is vital for maintaining high system integrity, resilience, and performance across a global production line.

View products

Anybus Communicator PROFINET IO-device - PROFINET IO-device

Anybus Communicator EtherNet/IP adapter - EtherNet/IP adapter