In today's rapidly evolving world, wireless technology is becoming increasingly popular among companies looking to establish connectivity in industrial environments. And it’s easy to see why. Compared to wired installations, wireless infrastructure offers clear, practical benefits, such as lower costs, improved flexibility, and increased uptime. With experienced partners on hand to ensure a smooth installation, switching to wireless technology is a smart choice for any company looking to stay ahead of the game.

Manufacturing is a competitive and constantly evolving industry. Consumers want customized products, and they want them now. To keep up with market demands, companies need reliable factories capable of automation and flexibility.

This section explains how wireless technology can help companies meet the ever-evolving industry demands.

Improved flexibility is one of the major advantages of wireless technology in industrial automation. Traditional wired installations may not be practical for machines that are continuously in motion, such as cranes, turntables, and lifts that rely on slip rings and drag chains. These machines may be limited in their mobility or pose a risk of damage to cables due to collisions or entanglements. Moreover, existing infrastructure or obstacles within the factory may make it challenging to install a network cable. Companies may also want the ability to easily move or remove the installation.

Wireless technology enables companies to overcome these problems by installing devices on machines to enable them to communicate wirelessly with access points (APs). Companies can strategically place APs throughout the facility, extending wireless connectivity to hard-to-reach or mobile machines. As a result, companies can create more flexible and adaptable systems that can easily accommodate changes in the production line or facility layout. This capability is particularly beneficial in environments where frequent adjustments are needed, allowing for seamless adjustments to be made without disrupting production.

Image 1: Mind the gap: Wireless technology can connect machines in hard-to-reach locations.

The harsh conditions in industrial environments mean that cables and connectors have a shortened lifespan. Connectors become worn from constant use. Both the connectors and cables suffer damage from extreme temperatures, constant vibrations, or accidental collisions. The cables and connectors can only take so much abuse before breaking, and when they do break, production grinds to a halt, resulting in lost time and revenue.

Wireless connections offer a reliable solution to these issues, as they do not suffer from wear and tear like cables. By switching to a wireless alternative, companies can avoid unplanned downtime and maintain uninterrupted production. This makes wireless connections a practical choice for companies experiencing issues with broken or damaged cables.

For example, bakeries often use cylinder-shaped containers mounted on a carousel to mix dough, as shown in image 2. The continuous rotation of the containers results in wear and tear on the slip rings used for control data, leading to eventual breakage. By implementing wireless connections, bakeries can eliminate the risk of connector failure and ensure a reliable production process.

Image 2: Connecting cables to constantly moving machines, such as cylinders used in bakeries, leads to cable wear and tear, resulting in downtime. A better option is to use wireless infrastructure to establish the connection.

Wireless technology enables companies to access data remotely, making it easier to monitor machines or production lines. Portable devices such as handheld HMIs allow companies to quickly and easily check equipment without needing to connect to the machine using a cable. This is particularly useful when accessing a PLC’s webpage or machines that do not have built-in HMIs.

In addition, accessing data remotely also enhances operator safety, as they are no longer required to climb long ladders, descend into the depths of a mine, or enter any other unpleasant or potentially dangerous environment to check equipment.

Wireless infrastructure is a cost-effective alternative to wired installations. The initial installation is faster and less expensive since there is no need to purchase and install expensive cables. Furthermore, maintenance costs are significantly reduced as there are no broken connectors or cables to replace.

Wireless networks are more flexible, making it easier to modify or scale the installation to adapt to changing market needs. This reduces the need for costly infrastructure upgrades in the future, further saving you money.

Early industrial wireless implementations often used technology designed for IT applications installed by IT professionals unfamiliar with harsh industrial environments. Consequently, these installations frequently suffered from unreliable connections, leading to misconceptions that wireless technology was unsuitable for industrial use.

Unfortunately, many of these misconceptions persist to this day. This section aims to dispel common misconceptions about wireless implementations in industrial environments.

![]()

When implemented correctly, wireless installations can be as reliable as wired installations. The challenge is to mitigate radio interference and ensure that signal strength is sufficient throughout the required area.

If you have in-house expertise, you can install the wireless infrastructure yourself. However, if you're uncertain about how to overcome these challenges in an industrial environment, it's best to seek help from experts such as Anybus. They can conduct a site survey and then use established techniques to establish a reliable wireless installation.

By selecting the right products and installing them in optimal locations, you can enjoy the benefits of wireless connectivity while ensuring reliable performance in your industrial setting.

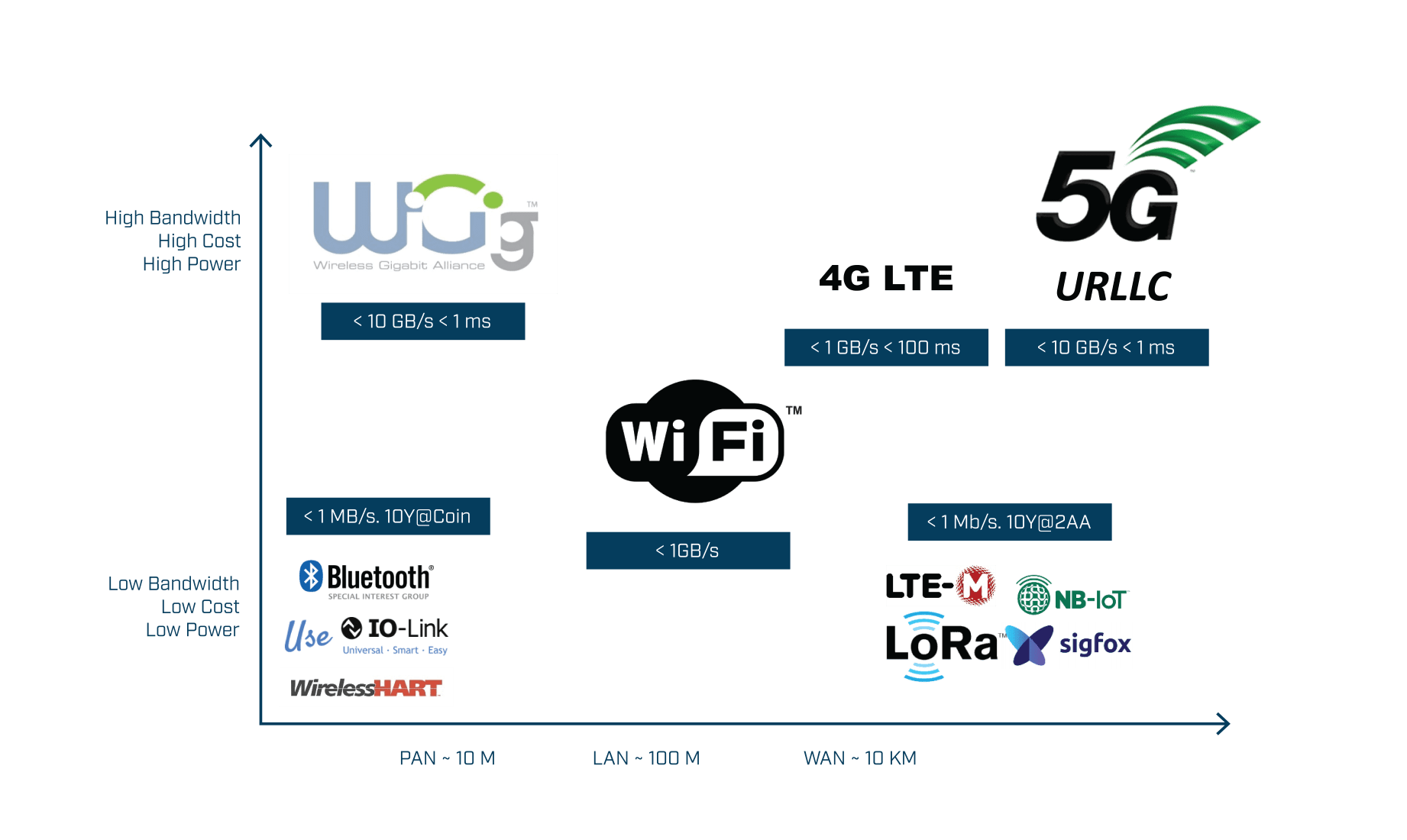

Each new wireless standard offers better performance, increasing the likelihood of finding a wireless technology that meets your needs. It's crucial to identify your requirements and compare them with the available standards to determine the best match. For low-bandwidth and low-power connections, Bluetooth is an excellent option. However, for high-bandwidth and real-time synchronization applications, Wi-Fi or cellular may be a better choice.

By evaluating your needs and selecting the appropriate technology, you can ensure that your wireless connection meets your requirements.

Each new wireless standard offers better performance, increasing the likelihood of finding a wireless technology that meets your needs.

Security is paramount in industrial automation, and some companies are reluctant to adopt wireless infrastructure due to concerns about increased vulnerability to hacking. However, there are several established methods to mitigate security risks, such as implementing strong encryption and authentication mechanisms and using network segmentation to isolate devices and data.

It is important to note that security in industrial wireless networks is a continuous process. Companies must regularly review and update their security measures to ensure that they remain effective in protecting their networks against evolving threats.

Every installation presents unique challenges, whether it's a complicated building layout, harsh environmental conditions, or the need to integrate wireless installations with existing wired equipment.

This section explains how you can solve these issues to ensure the installation’s success.

The best way to ensure success is to work with a company with proven experience in implementing wireless infrastructure in industrial environments. Experts can advise what will work and, equally importantly, what won’t work.

The experts will help you with every step of the installation process, ensuring you get the most from your investment. They will conduct a predictive site survey to assess signal coverage, identify optimal locations for access points, mitigate interference, and select the correct antenna type and angle.

Additionally, they will help you select and install equipment that meets industrial certification standards, and once the installation is complete, they will validate that it meets all necessary requirements.

While wireless technology is becoming increasingly prevalent, cables still dominate the industrial landscape. A pragmatic approach is to mix wireless infrastructure with the existing wired infrastructure. Keep the cables if the cables are working well with a hard-wired machine. But if you’re expanding or building a new site, check if wireless technology meets your requirements. Equally, consider replacing cables with wireless technology if you encounter any of the following issues:

By combining cables and wireless technology, companies can enjoy the best of both worlds.

By combining cables and wireless technology, companies can enjoy the best of both worlds.''

How can Anybus help?

Anybus can help ensure your industrial wireless installation goes smoothly by providing ready-made products and expertise.

We offer a comprehensive range of Bluetooth, Wi-Fi, and cellular products, providing you with the flexibility to choose the wireless technology that best suits your needs. Explore our range of wireless products for more information:

If you're unsure which wireless technology to choose for your application or need help with installation or troubleshooting, our team of wireless experts is ready to assist you. They have the professional knowledge and experience to provide you with the guidance and support you need.

Contact us today to learn more