White papers

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

During the Conticabana driving event, approximately 2,300 international guests experienced the importance of tire pressure. Data from the cars were retrieved using Ixxat FRC-EP190 and FRC-EP170.

Road safety depends on many factors: the driver, traffic management systems, a properly working vehicle etc. Essential for the safety is the contact between the tires and the road. Without good adhesion, one can neither steer, brake nor accelerate properly.

In short: all systems are useless if the tire has no grip. To experience this in practice, the tire manufacturer Continental organized an event where press representatives and customers became test drivers. Intelligent embedded systems in the test vehicle registered data from the car and transmitted them wirelessly to an external analysis computer. This way, a documented analysis could be generated for each driver.

The time schedule was perfectly met and the interaction of the components with the designated vehicle was perfect. In numbers, it was 20 man-months compared to 80 man-months which would have been required without the Ixxat solutions.

Nels von Schnakenburg, Section Manager of Technical Event Management

Approximately 2,300 participants from the press, OEMs and tire dealers participated in a several weeks long event around the topic of vehicle dynamics, organized by Continental Reifen Deutschland GmbH. In different test series, the behavior of modern tire design was analyzed in order to show the latest insights regarding the performance of modern tires.

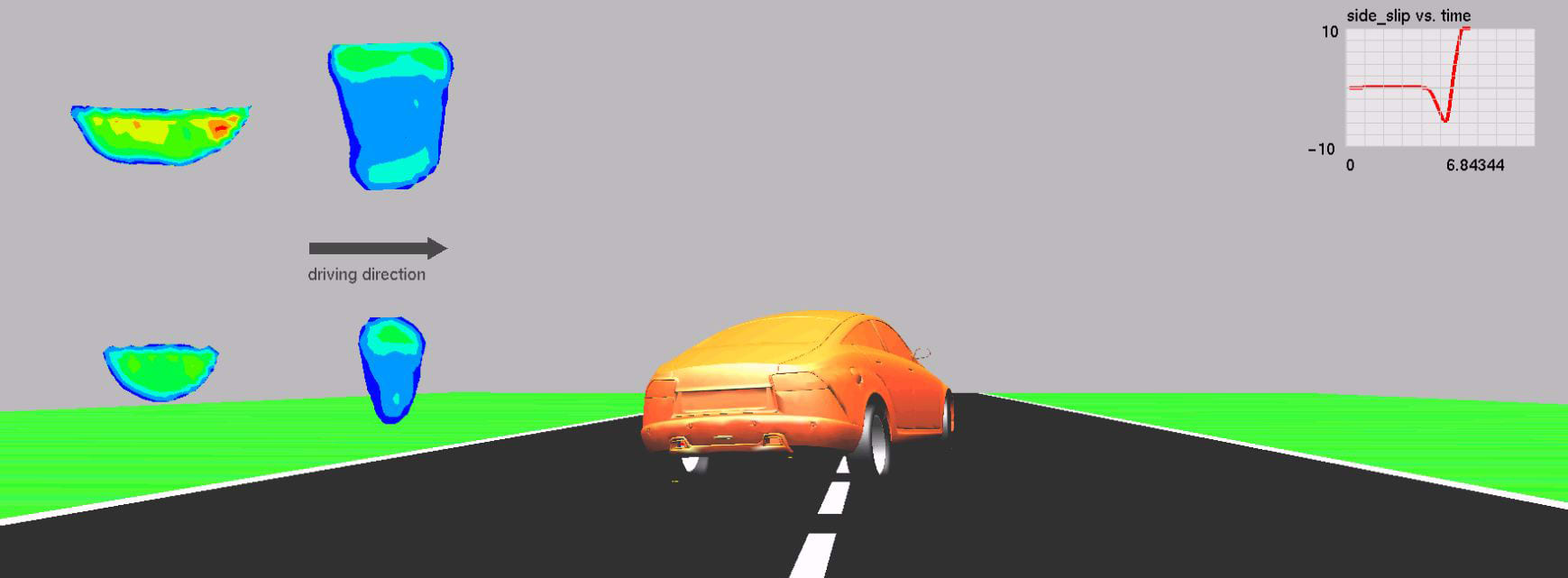

At the driving station “Under Pressure,” Continental presented a simulation where a vehicle in front lost its cargo and the test driver had to brake and take evasive action (see image above). Different tire pressures were measured and recorded and the data was transmitted wirelessly from the test car to a server and analyzed online.

Preparations were carried out under supervision from Nels von Schnakenburg, Section Manager of Technical Event Management at Continental and Christian Cramer from the Test Method Development & Vehicle Dynamics. They explain the test methodology: “We selected a suitable vehicle for this test, a medium-sized sedan with excellent handling dynamics. To analyze every individual test drive, internal sensors were installed in the car for mapping vehicle dynamics. The data was extracted, transmitted and visualized from the test drives. Both the load of the tire contact area and the different vehicle responses could be respectively visualized.”

This image shows the online analysis of a guest’s lane change. The rear instability felt by the customer can be explained by means of footprint analysis (seen at top left). The reduced tire pressure on the rear axle can no longer sufficiently build up the necessary lateral force to keep the car straight.

But Continental needed to find a way to get data from the cars to the analysis system without making interventions in the complex bus system of the vehicle. To do so, the tire manufacturer turned to HMS’s Ixxat solutions. The Ixxat solution consists of an embedded platform which consolidates different bus systems in a single device. The platform can handle different protocols innately and was therefore perfect for the implementation.

The data was extracted by Ixxat FlexRay-to-CAN gateways with adjusted configuration and analysis tools in the vehicle, transmitted wirelessly to be processed and visualized externally.

The alternative of a purely CAN-based solution was quickly dismissed since that would have required a vehicle less suitable for the tests – driving dynamics simulation would have been significantly harder to do.

Measuring instrumentation for recording the vehicle movement data were placed in the trunk and transmitted wirelessly to the analysis room.

In addition, equipment reliability was of utmost importance asince repeatinged of individual test drives wereas not possible within the tight time frame. Mr. von Schnakenburg explains: “The solution included the hardware components FRC-EP190 and FRC-EP170 in connejunction with Ixxat’s gateway configuration software. In approximately five months, we implemented the measurementing technology including the wireless solution.” Christian Cramer adds: “The time advantage is a strong advantage compared to all other solutions according to our experience. Furthermore, the Ixxat solutions offer add onfurther advantages such as modularity and flexibility, high temperature ranges, which areis important for on-board use, high data quality as well as intuitive FlexRay to CAN conversion. Other advantages are logging functionality and platform-independent visualization, as well as sustainable extensions such as to CAN-FD.”

“The time schedule was perfectly met and the interaction of the components with the designated vehicle was perfect. In numbers, it was 20 man-months compared to 80 man-months which would have been required without the Ixxat solutions – approximately 9600 saved working hours, which also benefited the budget,” reports Mr. von Schnakenburg. “Since all technical components interacted perfectly and the system worked reliably during the entire event, also the marketing and sales departments could benefit and Continental could distinguish itself as an innovative partner for tires, vehicle and driving tests.”

Stay up to date on the latest topics and gain industry insights from HMS' experts through our white papers, providing valuable knowledge and analysis.

Our products solve everyday industrial communication problems. Discover how our customers have improved their business with HMS case studies.

HMS communication solutions help thousands of companies solve specific communication problems in many different industries and applications.