Q&A

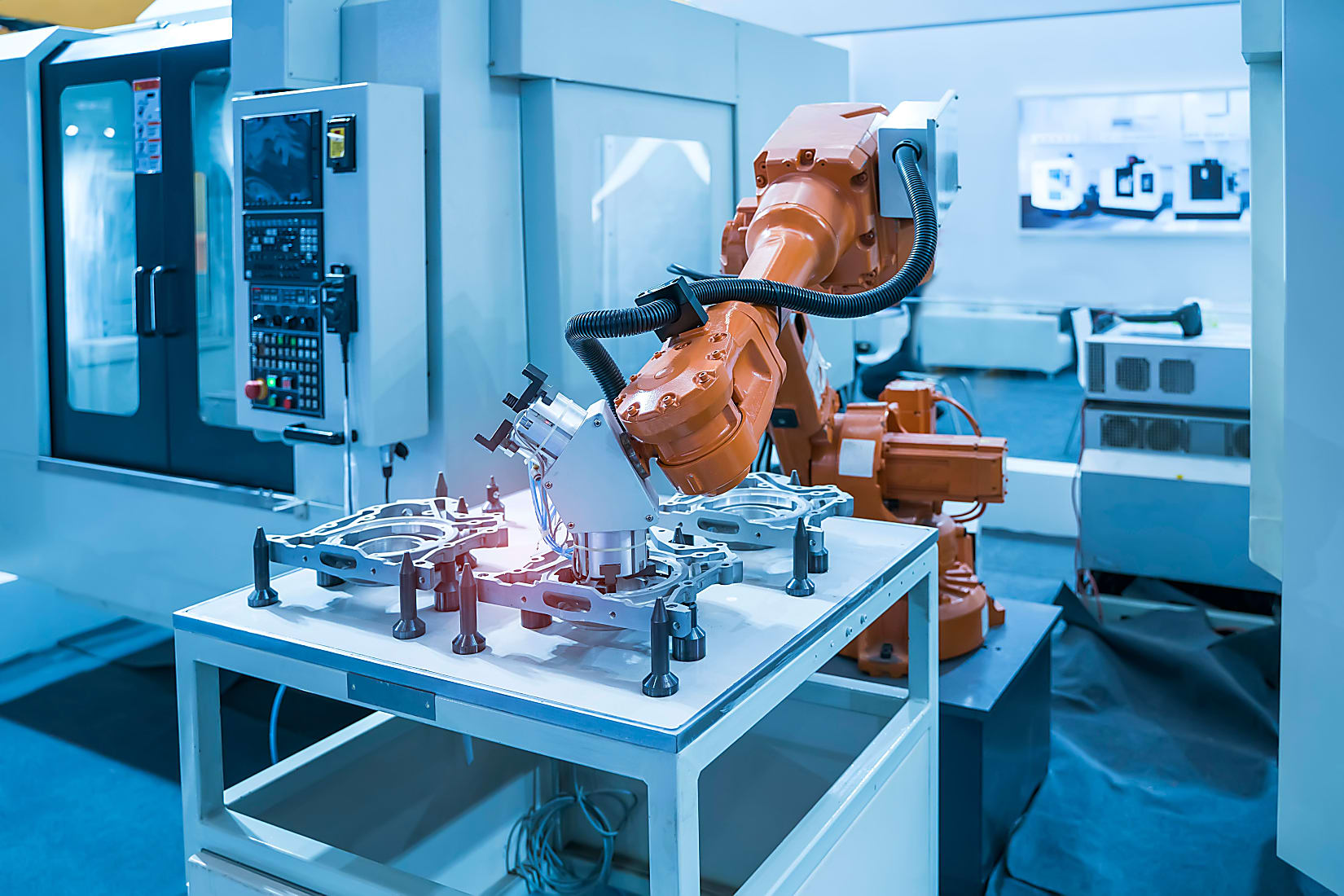

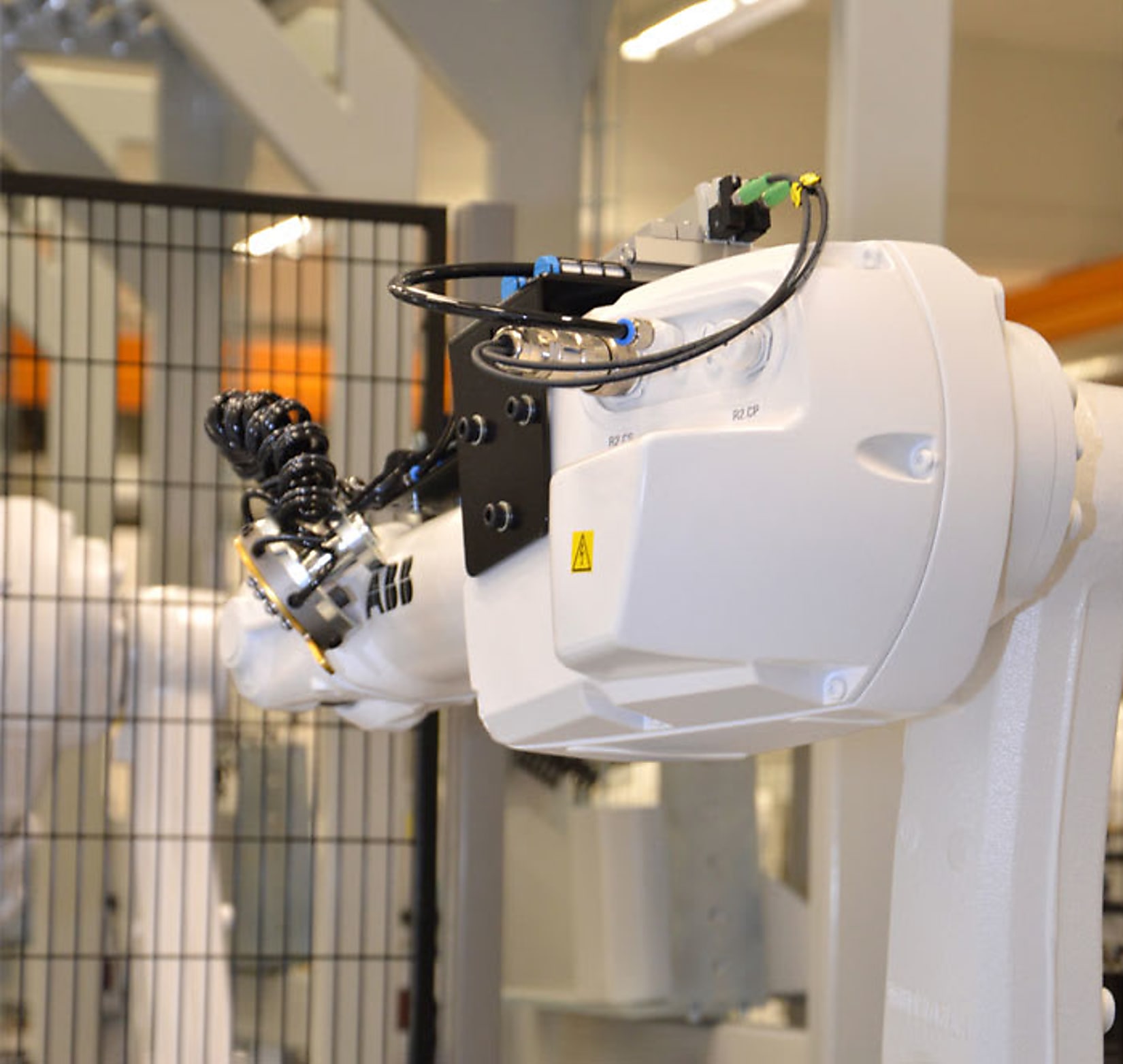

What is a Robot Controller?

Robot controllers are pivotal in robotic systems, functioning as the robot's "brains" to control movements and operations with precision. They ensure the robot performs tasks accurately and efficiently.

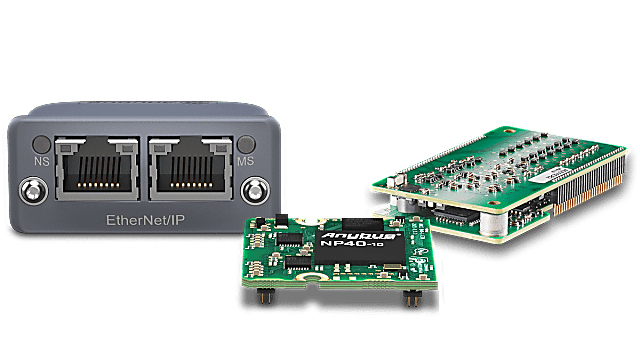

What communication networks does a robot controller use?

Robot controllers can use a wide variety of network protocols. They may use serial interfaces like RS-232 and RS-485, CAN communication, fieldbus protocols such as DeviceNet and Profibus, Industrial Ethernet protocols such as EtherNet/IP, PROFINET, and Modbus TCP are becoming increasingly popular. The choice of protocol often depends on the specific application, industry standards, and the requirements of the robotic system.

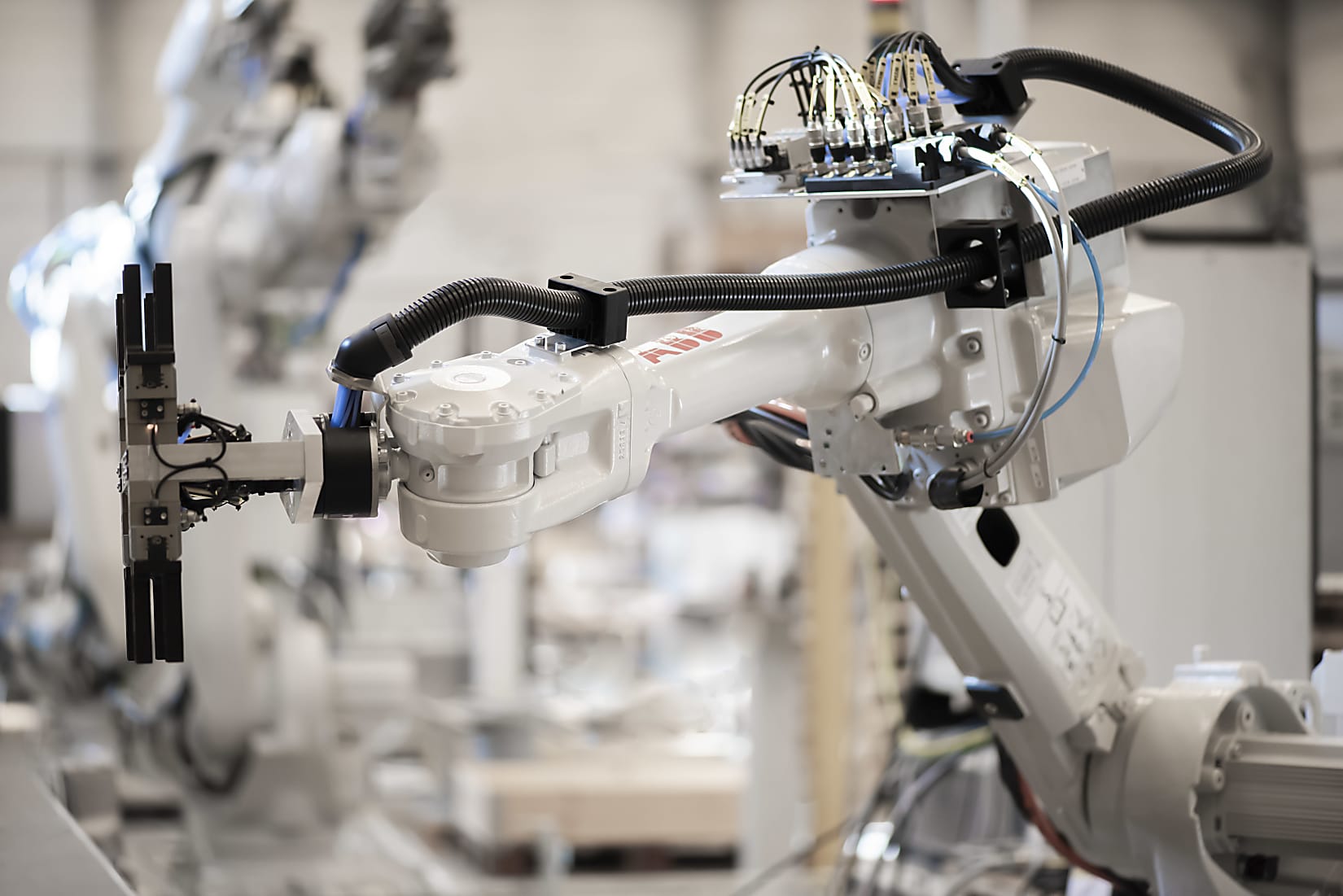

Are they safe?

To ensure safety, robot controllers must be designed with safety as a paramount consideration, adhering to industry standards such as EN ISO 13849-1 and EN IEC 62061. The controllers must incorporate essential safety features, including emergency stop functions, safety monitoring, and compliance control mechanisms, to effectively minimize risks and maintain a secure operating environment within robotic systems.